RADEL® POLYARYLSULFONE (PAS) Key Facts

RADEL® Polyarylsulfone offers outstanding thermal resistance, high impact strength, transparency, and hydrolytic stability.

RADEL® Polyarylsulfone is a high temperature material possessing a superior combination of properties. It competes in high performance applications not only with other engineering resins, but with metals, glass and ceramics, offering significant advantages

Key Features of RADEL® POLYARYLSULFONE (PAS)

- Thermal stability for extended use

- Excellent toughness

- Superior steam and boiling water resistance

- Transparency

- Exceptional creep resistance

- High heat deflection temperature

- Good stress-crack resistance

- Good electrical properties

- Injection mold ability to close tolerances

- Desirable combustion characteristics

Thermal and Chemical Properties of RADEL® POLYARYLSULFONE (PAS)

The outstanding thermal resistance of RADEL A will allow long-term exposure of finished parts to elevated temperatures.

RADEL resins are soluble in a limited number of organic solvents, including methylene chloride, dimethyl formamide and dimethylacetamide. Excellent hydrolytic stability is a particular attribute of sulfone based polyarylethers, and RADEL resins are highly resistant to mineral acids, alkali and salt solutions even under stressed conditions at elevated temperature.

RADEL resins have improved resistance to environmental stress cracking compared to UDEL® Polysulfone and significantly better performance than polycarbonate and poly(ester-carbonate). This is especially observed with chlorinated hydrocarbons. The most aggressive solvents leading to stress crazing or cracking include the ketones, esters and aromatic hydrocarbons. The least aggressive systems are the aliphatic hydrocarbons and alcohols.

Stress cracking resistance in aggressive environments is a function of many factors including molded in stress, applied stress, temperature and exposure time. Whenever questionable conditions exist, specific tests should be run reproducing actual conditions as closely as possible.

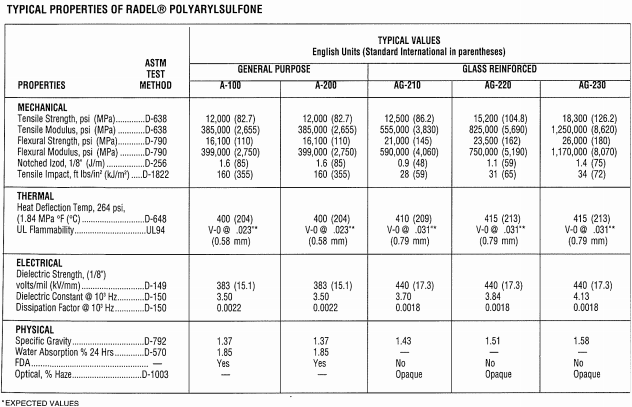

Typical Properties of RADEL® POLYARYLSULFONE (PAS)