Facts About ULTEM™

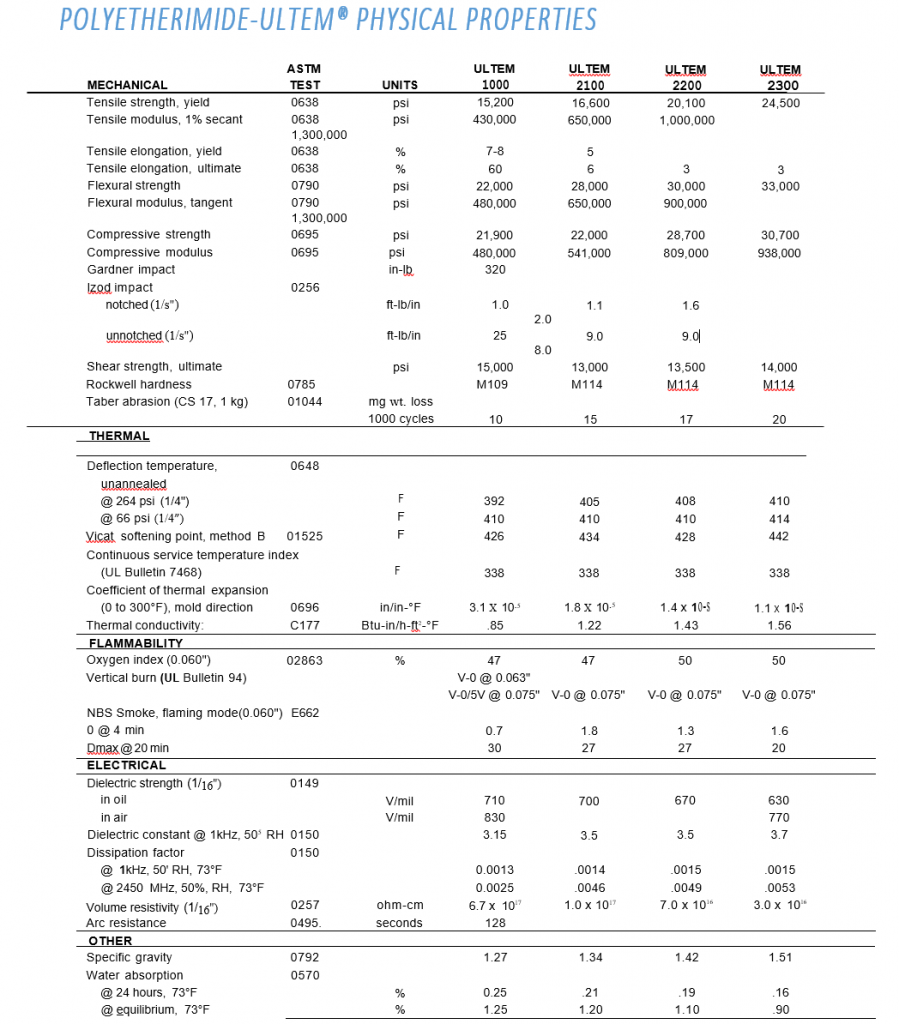

Ultem™ is the high performance material without the premium cost. With a continuous use temperature of 338°F, Ultem™ bridges the temperature between nylon, acetal and polycarbonate, and the high temperature/high cost thermoplastics such as polyimide and PEEK.

Ultem™ is a polyetherimide material most noted for its high strength and rigidity at high temperatures, long-term heat resistance, and stable dimensional and electrical properties. Ultem™ also offers broad chemical and flame resistance.

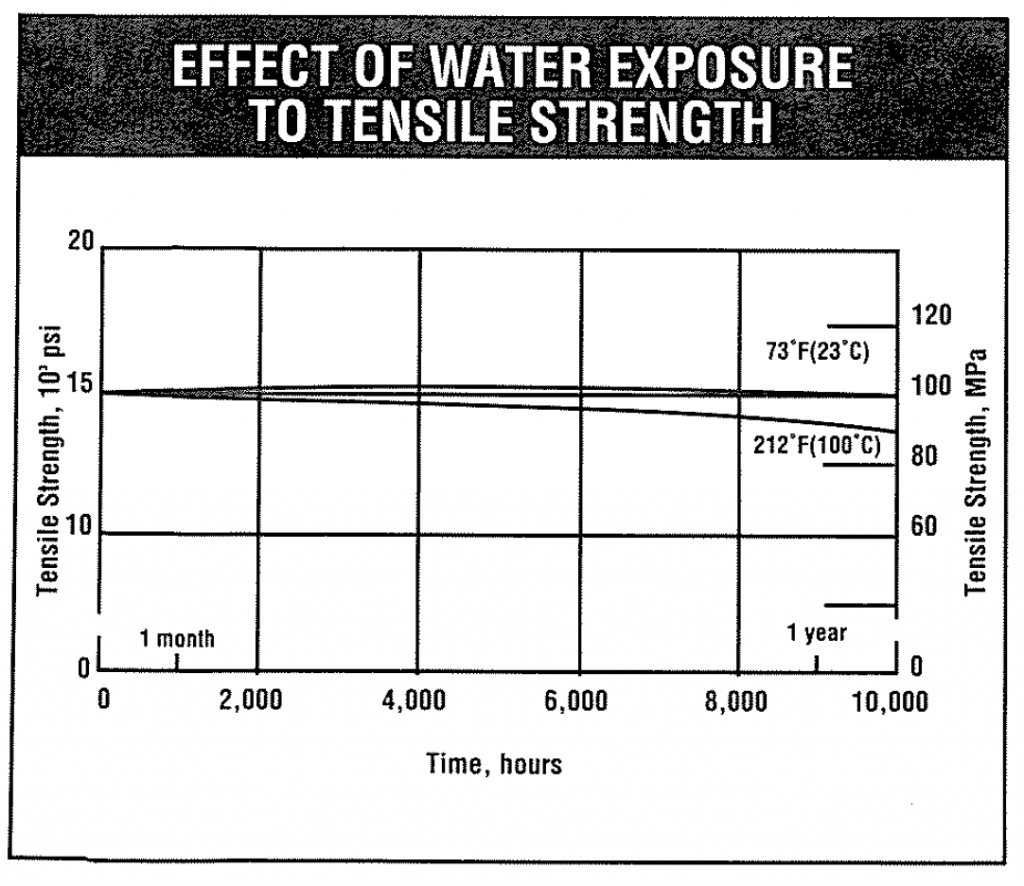

Not only does Ultem™ excel in hot air environments, but in hot water as well. Its hydrolytic stability is very good with 85% of the tensile strength retained after a 10,000 hour boiling water immersion, and 100% tensile strength retention after steam autoclaving 2,000 cycles at 270°F. It is also resistant to UV and gamma radiation, and offers resistance to creep at high temperature and stress levels.

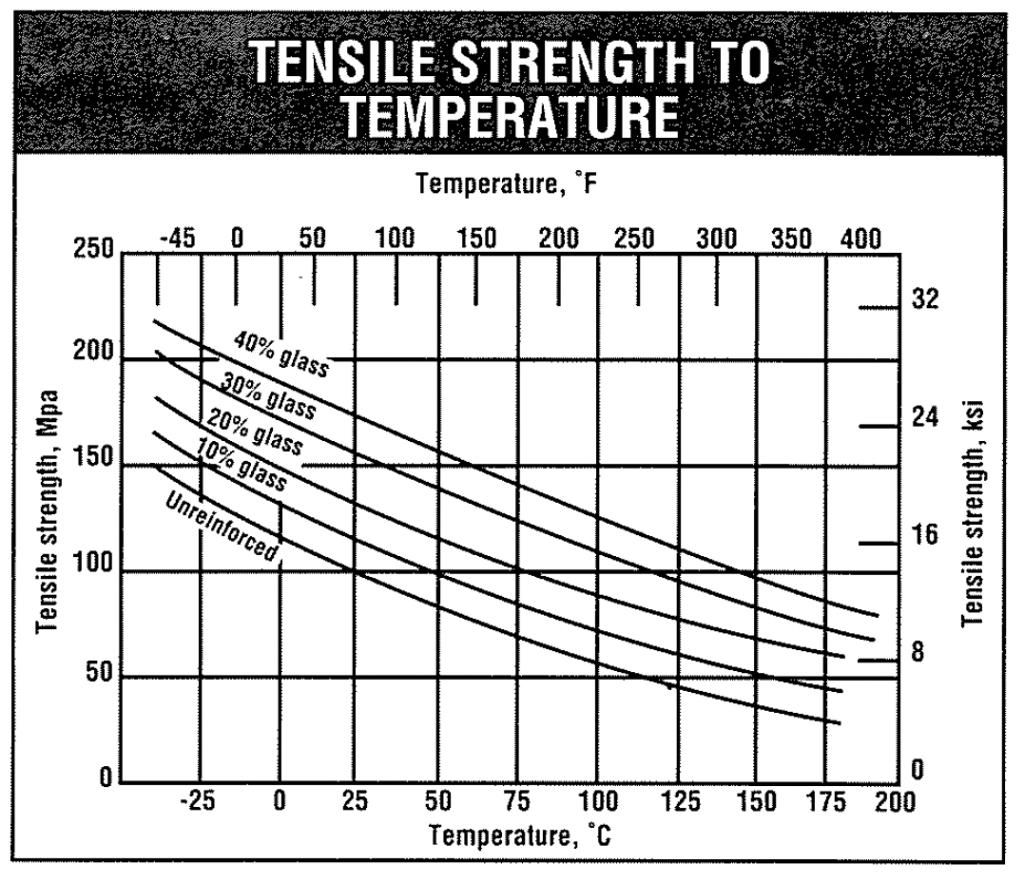

Glass reinforced Ultem™ provides even greater rigidity and dimensional stability. Glass reinforcement gives Ultem™ exceptional strength-to-weight ratio, and increases tensile strength to 24,500 psi, making it one of the strongest thermoplastic materials.

Ultem™ Key Features

- Broad chemical resistance

- Cost effective

- Diffusion Bondable

- Excellent finishing characteristics

- FDA compliance (Ultem™ 1000 F)

- Flame resistance with low smoke evolution

- Flame retardant per UL94 V-0 testing standards

- High dielectric strength- 830 V/mil (*second highest among HP plastics)

- Long term service (continuous use) temperature of 338°F

- Stable dielectric constant & dissipation factor

- Strength & modulus at elevated temperatures

- Superior performance in hot water

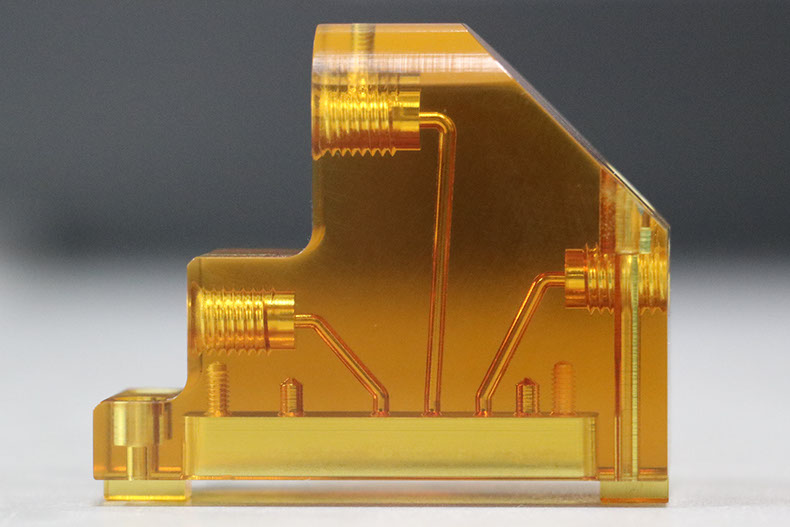

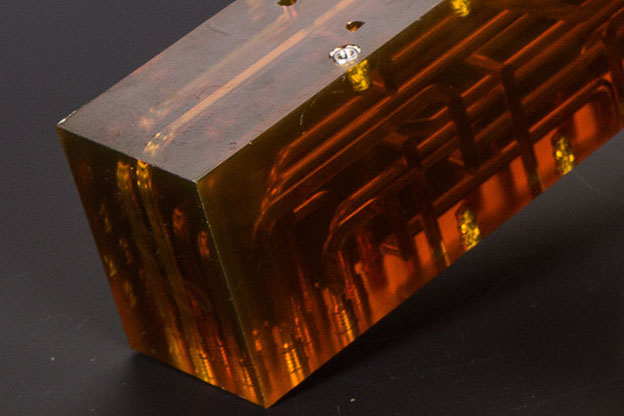

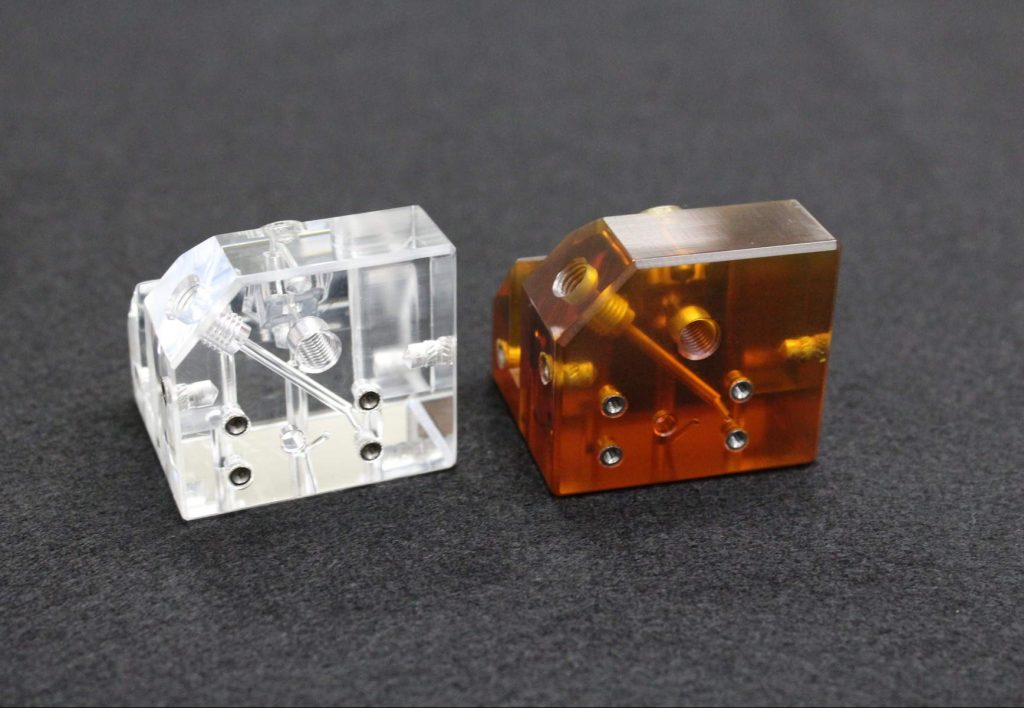

- Transparent (in thin cross sections)

Key Properties of Ultem™

- Transparency

- Autoclavable

- Gamma, ETO gas

- high ionic purity

- Resistance to lipids

- FDA/USP Class V1

- Resistant to blood, fat, alcohol

- ISO 10993 cytotoxicity

- Property retention after 300 autoclave cycles at 134 degrees C

- Competes with PSU & PES

Key Ultem™ Applications

Ultem™ is used in a variety of industries but it is especially prominent in the medical diagnostic field. Surgical tools, trays, handles, and test trials are all manufactured from this material due its ability to be cleaned for repeated use. Medical applications requiring resistance to steam autoclave, hot air, ethylene oxide, gamma radiation, and cold chemical sterilization utilize this material. Ultem™ is the material of choice in diffusion bonded manifolds where higher heat resistance, chemical resistance, and dimensional stability are required beyond cast acrylic abilities.

Typical Medical Applications of Ultem™

- Dialysis

- Fluid pumps

- Handles

- IVD Sets & Containers

- Oxygenators

- Short term joint replacement

- Sterilization trays

- Surgical tools

- Test trials

Other Select Ultem™ Applications

- Bonded manifolds

- Butterfly valves

- Filtration systems

- High temperature electrical insulators & connectors

- Luers

- Metal replacement

- Pipettes

- Silicon wafer chip processing

- Solenoid valves

- Stopcocks

- Transportation industry interior parts requiring flame resistance and low NBS smoke evolution

Ultem™ Shapes Available

Rod:

- Ultem™ 1000: 1/4″ – 6″ diameter

- Ultem™ 2300: 1/2″ – 6″ diameter

- Length: 2-8 ft. nominal

Plate:

Utem™ 1000: 1/32″ – 2″ thick

Ultem™ 2300: 1/4″ – 2″ thick

Width: 12″ or 24″

Length: 48″