Contract Manufacturing Capabilities

As a contract manufacturer for OEMs in the Life Science, Medical, Biopharmaceutical, Aerospace, and other industries, CMG has developed a diverse set of services and capabilities to support the requests of our customers. We continue to evolve, invest in technology and training, and develop new capabilities to suit the needs of our diverse customer base.

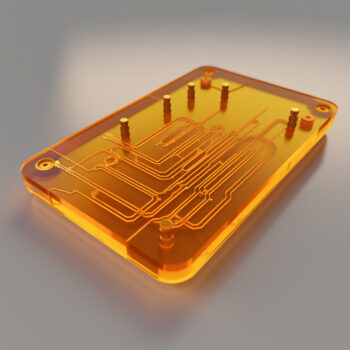

Diffusion Bonding of

Performance Plastics

Our proprietary bonding process allows us to fuse together multiple layers of a chosen thermoplastic at the molecular level, creating a permanent bond without the use of adhesives. This technology is especially valuable for OEM’s who need a contamination-free bonded manifold with many fluid paths concentrated into a limited space requirement.

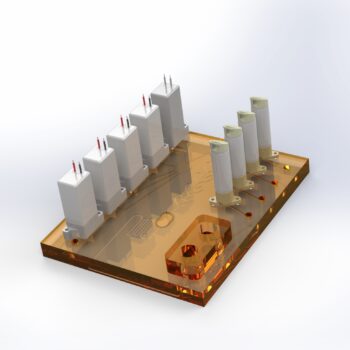

Manifold

Design Service

Design service for bonded and milled manifolds. Capabilities include 3D CAD modeling, flow simulation & analysis to reduce design iterations, rapid prototyping, testing for flow, leak, pressure, and more.

Contract

Assembly

Contract assembly services for manifolfds, valves, tubing, connectors, filtration, waste containers, level-sensors, and more.

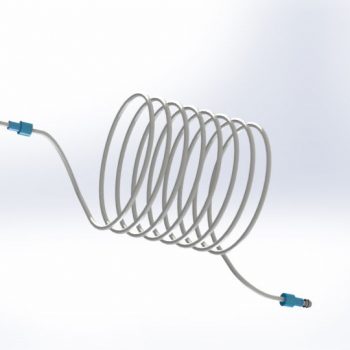

Custom Tubing

Flanges, Flares & More

A wide range of value-added tubing capabilities, including but not limited to: heat shrink labeling, thermoformed bends and coils, FormFit flanges, flares, tipping, cut-to-length, kitting, laser etching, ink-jet printing, UV adhesive curing, sterilization, and much more.

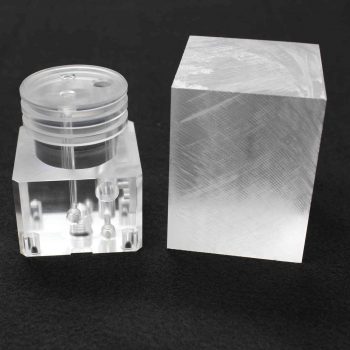

Precision Machining

Milling & Turning

At Piedmont CMG, we’ve been machining high performance plastics, engineering thermoplastics, and a wide variety of standard polymers for decades. OEMs turn to us for our depth and breadth of experience with the most critical components and fluidic hubs that are essential to the success of their applications. The latest high-speed CNC milling equipment and techniques are just standard operating procedure in our machining facility.

Rapid Prototyping

Quick turnaround & expedited lead time options from our rapid response team. Contact us to learn more and discuss options for your project.

Testing & Validation

Testing service to validate and certify that products meet or exceed customer requirements and specifications. Testing for flow, pressure, leak, function, and more.

Secondary Services

Secondary services include a range of operations that are completed during machining cycles as an added cost efficiency to the lean manufacturing production process. Vapor polishing, ultrasonic inserting, ultrasonic cleaning, laser engraving, part number & serialization, and much more.

Don’t see what you are looking for?

Talk to our customer service or sales team. There is a good chance that we can help you. If not, we can help guide you to an industry partner who can.