Advantages of Acrylic (PMMA) Diffusion Bonded Manifolds

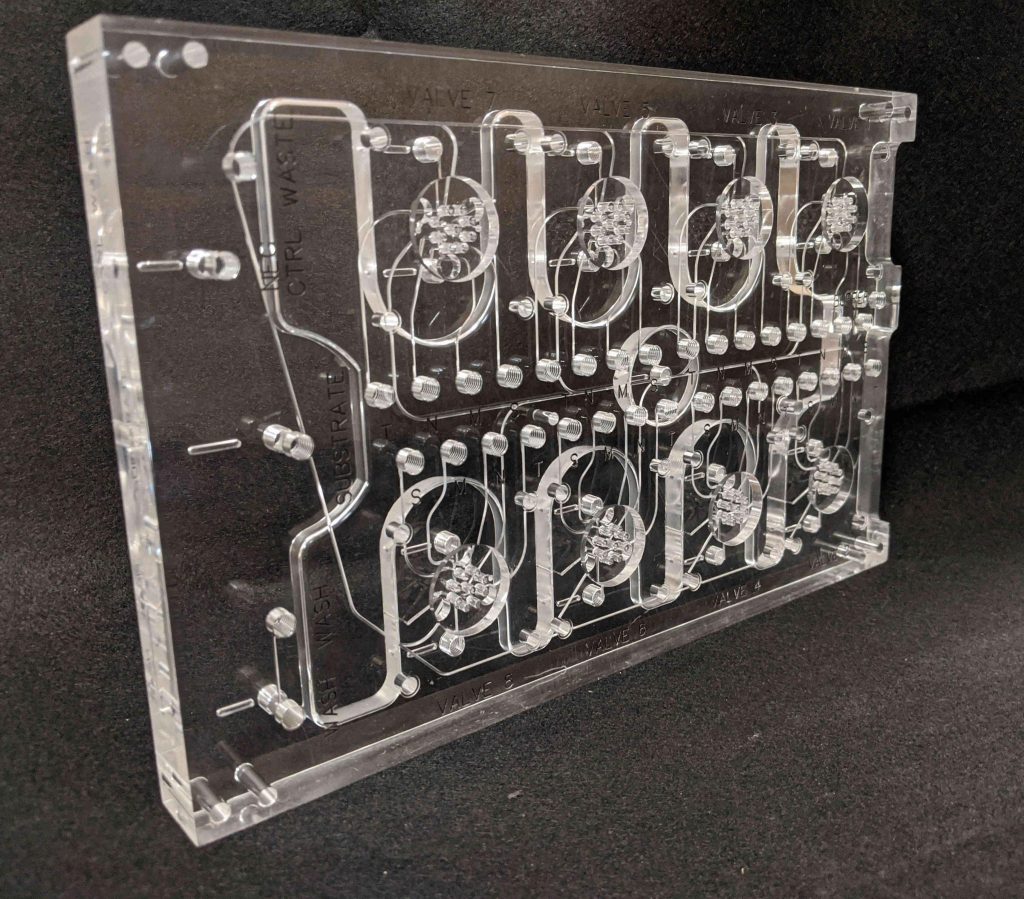

Diffusion bonded acrylic (PMMA) manifolds are made of a clear, lightweight material with many applications in the IVD industry. Acrylic manifolds are often chosen for their optical clarity, which can be obtained through machined surface finishes without the need for polishing. However, acrylic manifolds can also be buffed, vapor polished, and flame polished to achieve glass-like clarity and transparency.

Diffusion bonded acrylic manifolds are reasonably tough, have low water absorption, and are resistant to most mineral acids. Bonded acrylic manifolds also have good dimensional stability and do not support fungal growth, making them ideal for many fluidic applications.

Applications of Diffusion Bonding Acrylic Manifolds

These manifolds are frequently used as fluidic hubs in instruments for various industries, such as: IVD, clinical chemistry, life sciences, laboratory research, pharmaceuticals, and other medical applications. Diffusion bonded acrylic manifolds often serve as wash stations, waste and water control hubs, and are utilized for their ease of use and design flexibility.

Disadvantages of Diffusion Bonded Acrylic Manifolds

Despite the many advantages of acrylic manifolds, the material does scratch fairly easily, can exhibit stress cracking when exposed to some chemicals or from inferior machining techniques, and has a maximum service temperature of 180 degrees F.