Thermoformed Flared & Flanged Tubing Assembly

CMG supports leading OEMs with customer-designed, value-added plastic tubing assemblies that control the flow of fluids throughout an application, whether carrying samples, reagents, or waste. These tubing assemblies often pair with our diffusion bonded manifolds to give design engineers confidence and total control over fluid movement from input to waste output, all in a chemically inert environment. Our value-added tubing assemblies are an easy fluid handling solution for OEMs developing medical, In Vitro Diagnostics (IVD), laboratory, clinical chemistry, life-sciences, and many other applications.

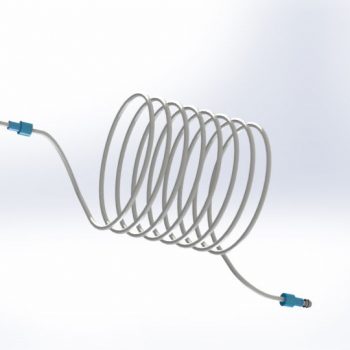

Piedmont CMG’s assembly facility offers a wide range of value-added tubing services: Heat shrink labeling, thermoformed bends and coils, flanges, flares, tipping, cut-to-length, kitting, laser etching, ink-jet printing, UV adhesive curing, sterilization, and much more.

Advantages of Formed Flared & Flanged

Tubing Assembly

The advantages of flanged tubing assemblies from CMG are numerous. Our custom FormFit flanges ensure a secure fit in any port, with no dead volume areas or carryover. The precise tolerances and uniform wall thickness on our proprietary FormFit thermo-molded flanges are repeatable and consistent, giving CMG unrivaled accuracy and flexibility of design.

Thermoformed tubing is another capability that gives increased flexibility of design and performance capabilities. CMG can form tight bends or coils to reduce space requirements. Tight spaces in analytical instruments can make it difficult to maintain consistent fluid paths with regular tubing. Heat formed tubing assemblies can be custom-designed with precision bends and coils that fit neatly into instruments and prevent kinks. Thermoformed coils take up the slack of moveable arms to prevent entanglement. Coils and other heat formed tubing are also regularly used in fluidic processing for mixing and other laboratory requirements. We develop our own tooling to manufacture customer specified coils, bends, or a combination of both. These features, along with the components detailed below, ensure ease of installation and service for your application.

Connectors & Fittings for

Fluidic Tubing Assemblies

Hardware and fittings allow various types of secure connections to other tubing, threaded ports, control valves, and many other components. We can integrate a variety of standard and custom components to fit your ideal design.

Custom Labels, Markers & Heat Shrink for

Tubing Assemblies

Plug & Play Assembled Tubing Kits

Fluidic Tubing Materials