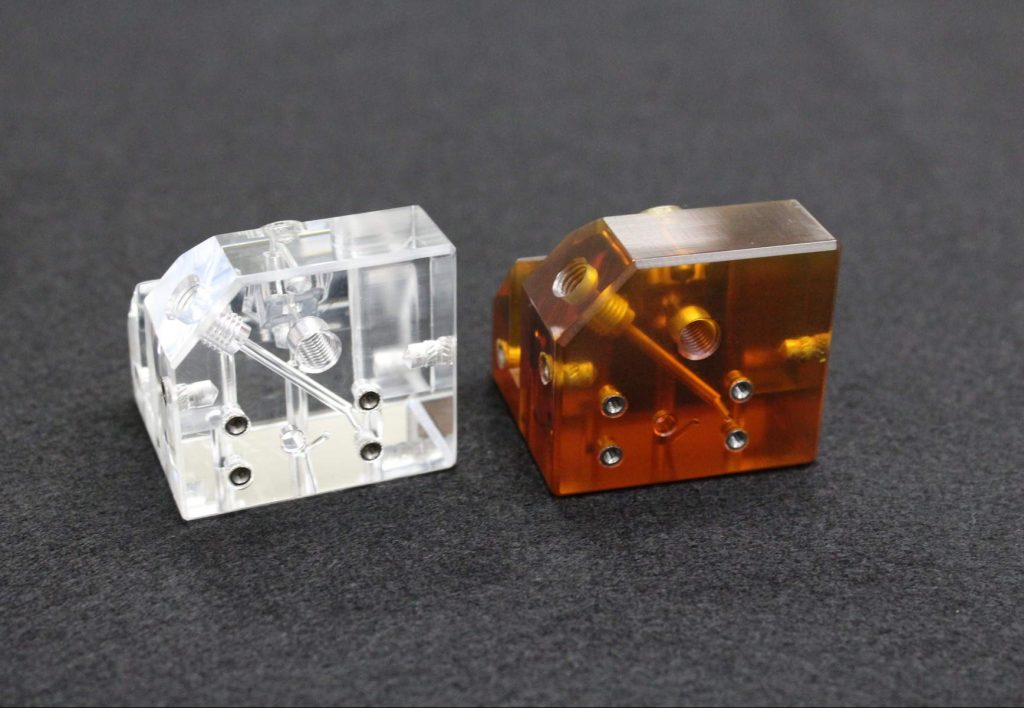

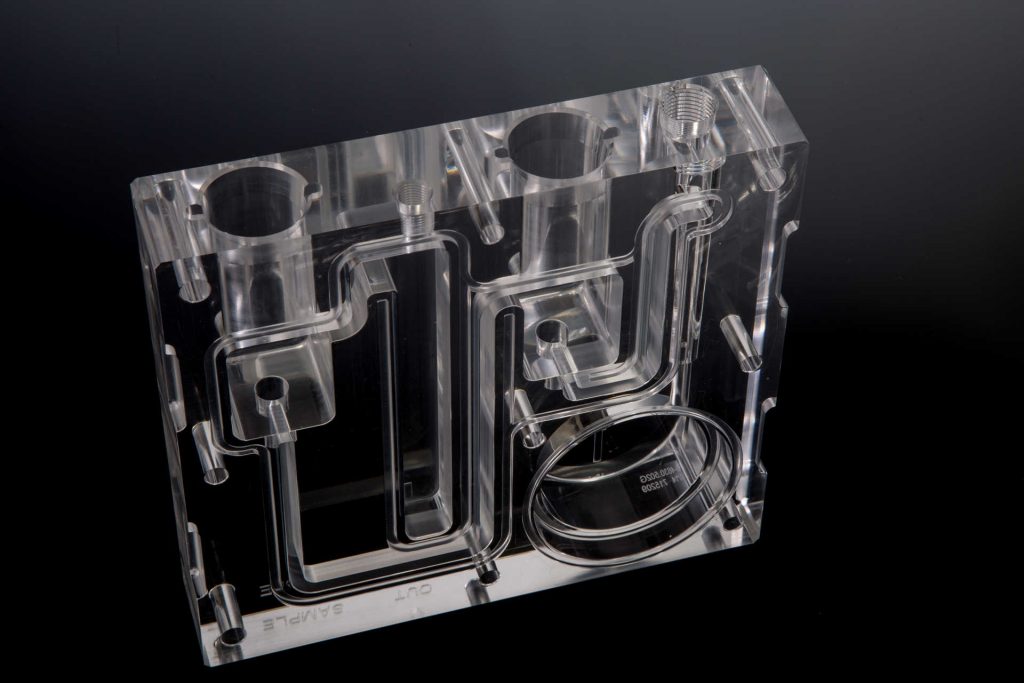

Machined Plastic Manifolds

Machined manifolds are a cost-effective solution for fluidic manifolds that only require straight fluid paths. This simplification of design allows machined thermoplastic manifolds to utilize a much wider range of high performance plastic materials. It also results in shorter lead times, faster prototyping, and cost savings for OEMs.

Materials Used for Machined Manifolds

-

- Polyether Ether Ketone (PEEK)

- High-density Polyethylene (HDPE)

- Polycarbonate

- Acrylic (PMMA)

- Ultem or Polyetherimide (PEI)

- Polyvinyl Chloride (PVC)

- Polysulfone (PSU)

- Noryl

- Ertalyte

- Teflon

- Acrylonitrile Butadiene Styrene (ABS)

- Isoplast

- Polyvinylidene Fluoride (PVDF)

This is not an exhaustive list. If you would like more information about materials for machined manifolds, see our engineering design guide or contact us to learn more.

Key Features of Machined Manifolds

Precision machined manifolds provide many of the same benefits and key features as diffusion bonded manifolds. Below are some features and elements that are commonly added or integrated in machined fluidic manifolds: