Lean Manufacturing Capabilities

Piedmont CMG’s decades of manufacturing experience in high volume plastic machining and manufacturing methods have given us a strategic advantage with expertise in modern lean business practices. Many members of the team have been involved in high volume precision injection molding utilizing robotics, heavy gauge thermoforming/pressure forming, and precision machining. Secondary inserting, assembly and inspection during cycle, work cell design, and utilization contribute to Piedmont CMG’s cost effectiveness and has proven achievement in throughput efficiencies.

Just in Time (JIT) Plastics Manufacturing

Piedmont CMG utilizes a systematic approach to eliminating waste through continuous improvement by flowing the product at the demand of the customer. One way of defining it is producing value (a product or a service) with less of everything (inventory, human effort, equipment and tools, plant floor, design and development, total cost etc.) to maximize the profit, while delivering a product of highest quality when the customer needs it, in the quantity needed. It means a commitment to minimize the total cost (a waste-free operation) while offering a product or service that is focused on your customer’s success.

Through utilizing and optimizing these practices, we are able to offer the highest quality product to our customers at the most efficient and effective cost for them. This translates to higher profits for our customers in their own manufacturing processes.

Our Goals In Lean Manufacturing

At Piedmont CMG, we pride ourselves in being the top precision plastics machining manufacturer in the world. In enacting lean processes and 5S practices throughout our facilities, processes, and staff training, we aim to accomplish our 4 goals which benefit our customers as much as they benefit us.

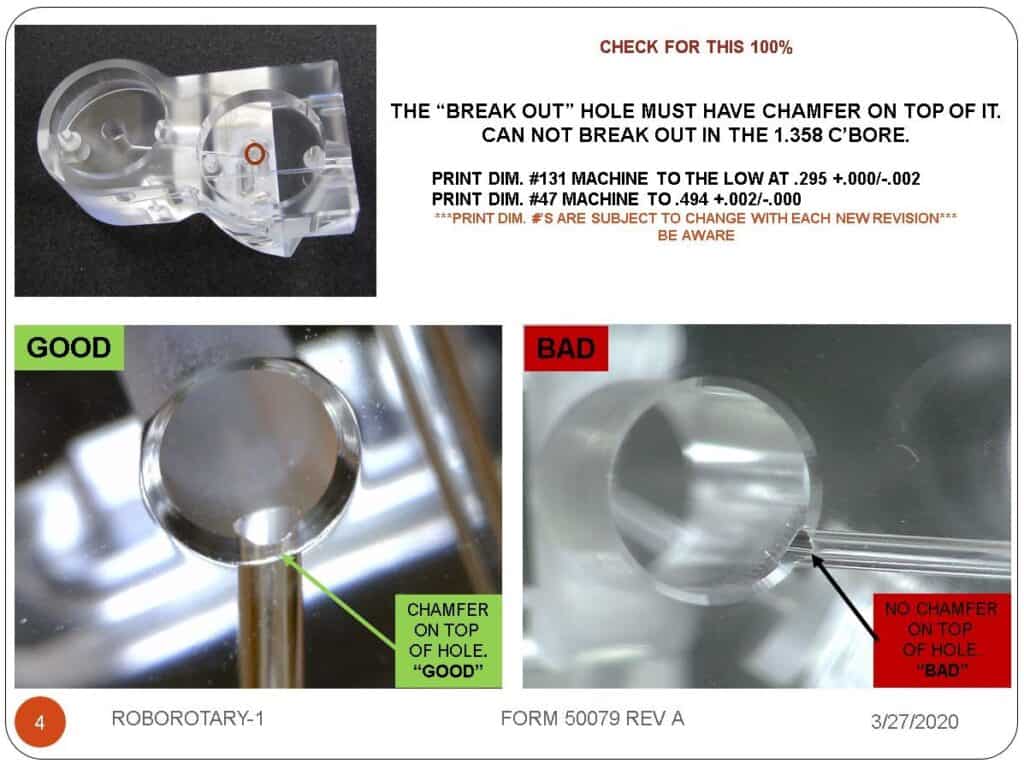

Improve Quality

To stay competitive in today’s marketplace, a company must understand its customers’ wants and needs and design processes to meet their expectations and requirements. Our main goal is to provide the utmost in quality for our customers by not just meeting, but exceeding our customers’ expectations.

Eliminate Waste

Waste is any activity that consumes time, resources, or space but does not add any value to the product or service. By eliminating waste in our processes, we are able to save time and money in our engineering and manufacturing services. These savings enable us to pass on those cost savings to our customers.

Reduce Time

Process improvement is a never-ending process and any manufacturer that says otherwise is wasting your time (and your money). That is one of core values of The CMG Difference. Reducing the time it takes to finish an activity from start to finish is one of the most effective ways to eliminate waste and lower costs for ourselves and our customers.

Reduce Total Costs

To minimize cost, a company must produce only to customer demand. Overproduction increases a company’s inventory costs because of storage needs.

Elminating Waste in Plastics Manufacturing

Piedmont CMG began investing heavily in lean processes over 10 years ago when we set goals to reduce the seven types of waste:

- Transport: Unnecessary movement of materials

- Inventory: Excess inventory not directly required for current orders

- Motion: Extra steps taken by employees because of inefficient layout

- Waiting: Periods of inactivity

- Overproduction: Occurs when production should have stopped

- Over Processing: Rework and reprocessing

- Defects: Do not conform to specifications or expectations

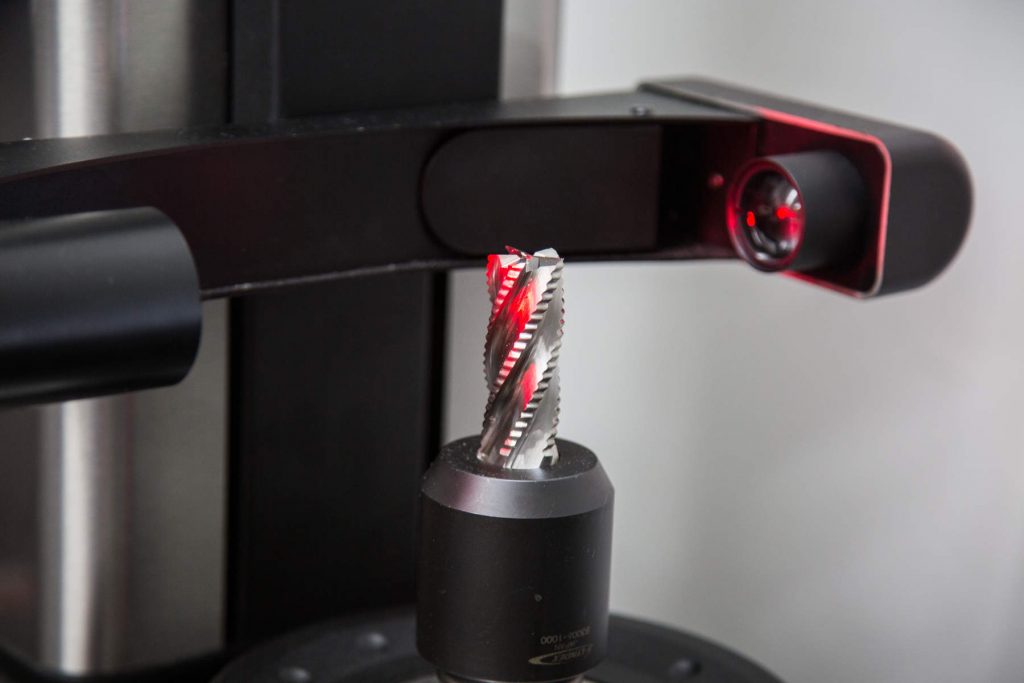

Total Productive Maintenance (TPM) for Plastics Manufacturing

Piedmont CMG adopted a process labeled Total Productive Maintenance (TPM). TPM is a maintenance program which involves a newly defined concept for maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same time, increase employee morale and job satisfaction.

Results of Implementing TPM

- A clear business culture is designed to continuously improve the efficiency of the total production system

- A standardized and systematic approach is used, where all losses are prevented or known

- All departments, influencing productivity, will be involved to move from a reactive to a predictive mindset

- A transparent multidisciplinary organization is reaching zero losses

- Steps are taken as a journey, not as a quick menu

Root Cause Analysis at Piedmont CMG

A root cause is defined as a factor that caused a nonconformance and should be permanently eliminated through process improvement. The root cause is the core issue – the highest-level cause – that sets in motion the entire cause-and-effect reaction that ultimately leads to a problem. Root Cause Analysis (RCA) is defined as a collective term that describes a wide range of approaches, tools, and techniques used to uncover causes of problems.

Piedmont CMG’s understanding of Root Cause Analysis is at the heart of one of our core values that defines The CMG Difference: Continuous Improvement. We do not simply band-aid problems. We seek out the root cause to ensure the entire process and the product we provide to the customer is functioning at the highest possible efficiency an quality.