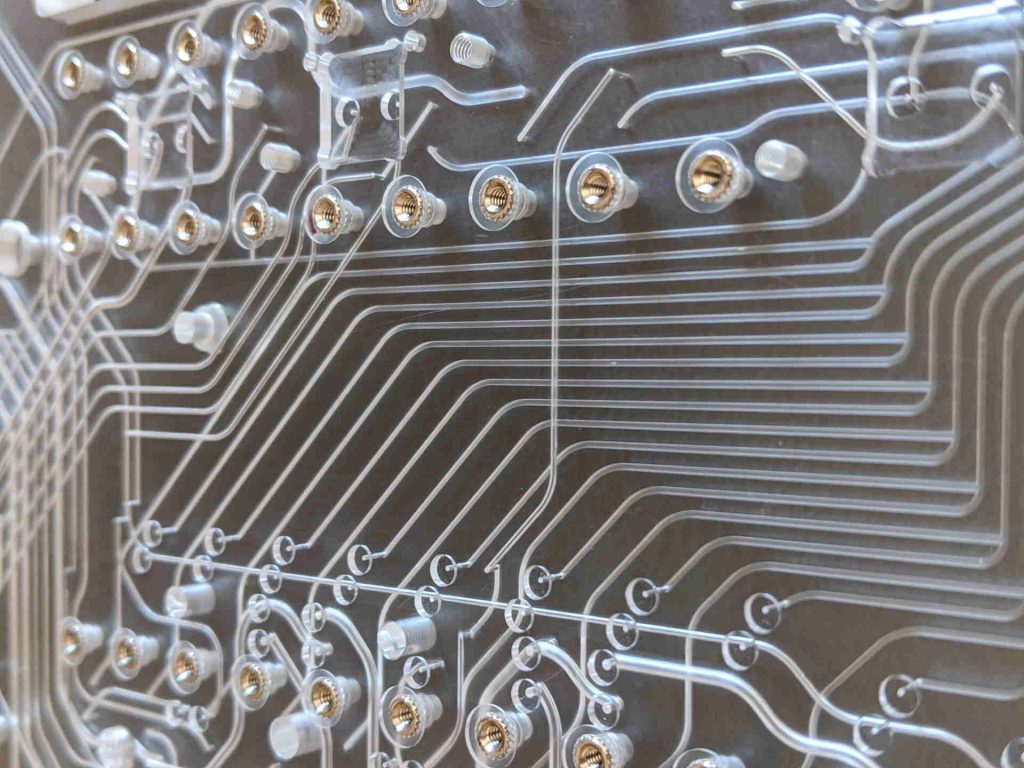

Ultrasonic Threaded Inserts for Plastic Parts

Ultrasonic inserting is the process of bonding metal inserts into plastic machined parts and manifolds without the use of any adhesives. Ultrasonic vibrations heat and soften the plastic machined part to allow the metal insert to be pressed into the part. Once the part cools, the metal and plastic are permanently bonded. The inserts themselves and the process of ultrasonic insertion is a cost-effective aid in mating fluidic parts together. Pumps, valves, solenoids and other components are mated to the plastic machined part with ultrasonic inserts.

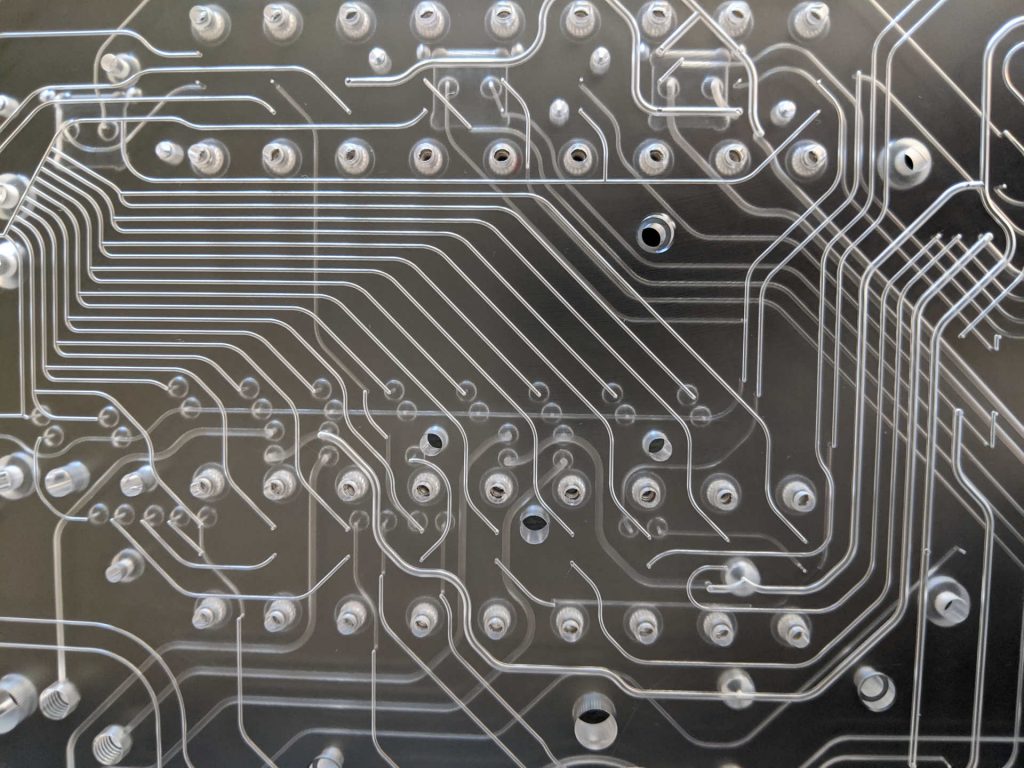

Relaxing Plastic for Long-Lasting Quality

Ultrasonic insertion is the best way to mate outside components to a manifold. But to ensure improved quality, Piedmont CMG will then heat treat your part to cement the inserted parts in a perfect bond. The advantages of this premium service mean your vital component will be stronger, last longer, and prevent the possibility of cracks.