What is a Manifold Assembly?

A manifold assembly is a crucial fluidic module that provides primary control of all the reagents, samples, rinse, and other fluids that flow throughout a device, from entry ports to waste tubing exit ports. Manifold assemblies typically integrate valves and/or pumps to push the fluids through tubing, manifolds, and sample test functions.

Top 10 Benefits of a CMG Fluidic Manifold Assembly

- Confidence in consistent, quality performance on every function for every sample.

- Supply chain consolidation for reduced costs and lead times.

- Faster, simplified installation and field servicing.

- Rapid delivery of stocked replacement parts.

- Smaller overall device footprint.

- Traceability for all components.

- Reduced reagent requirements per sample.

- OEM specified testing and validation with COC.

- Reliability of market leading diffusion bonding technology.

- Cost-effective manufacturing and assembly – made in USA.

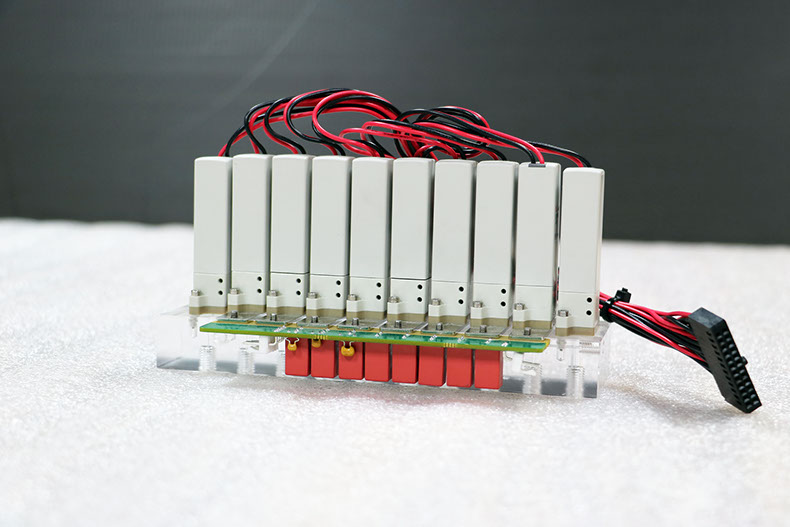

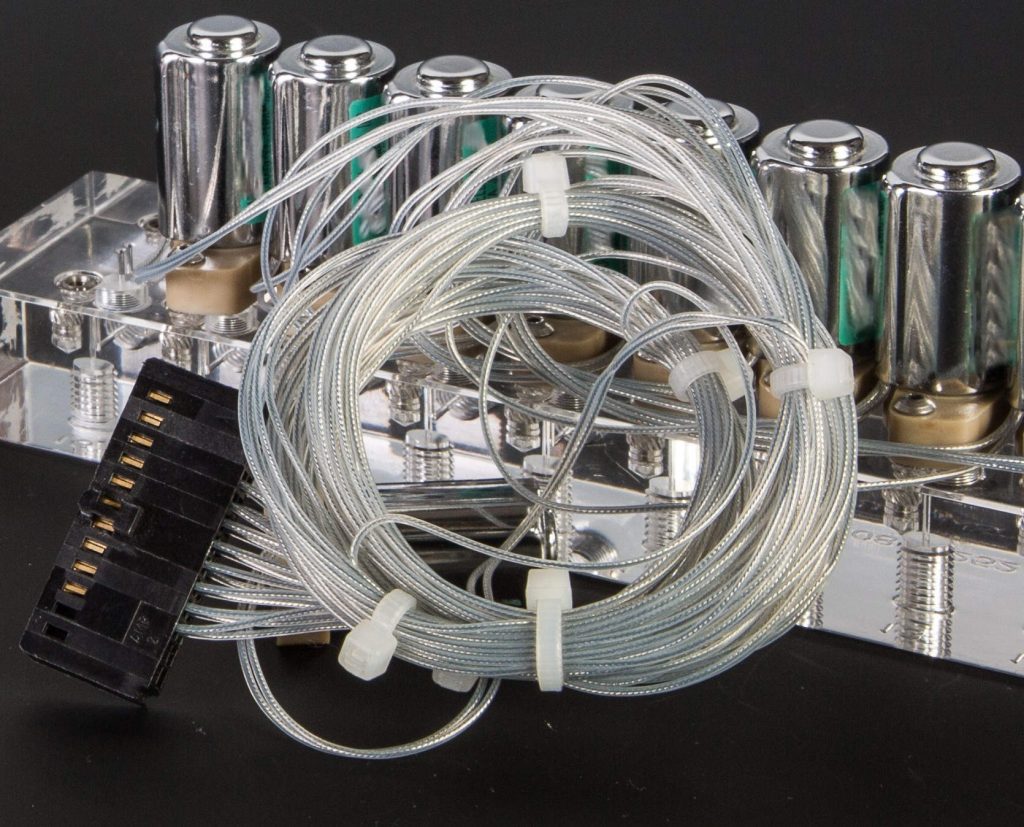

What components are in a Manifold Assembly?

- Diffusion bonded manifold

- Machined manifold

- Solenoid valves

- Shear valves

- Rotary valves

- Sensors

- Pumps

- Flow cells

- Mixing chambers

- Fluid channels

- Inlet & outlet ports

- Polymer tubing assembly kits

- Labels & markers

- Chips & electronic connectors

- Ultrasonic inserts

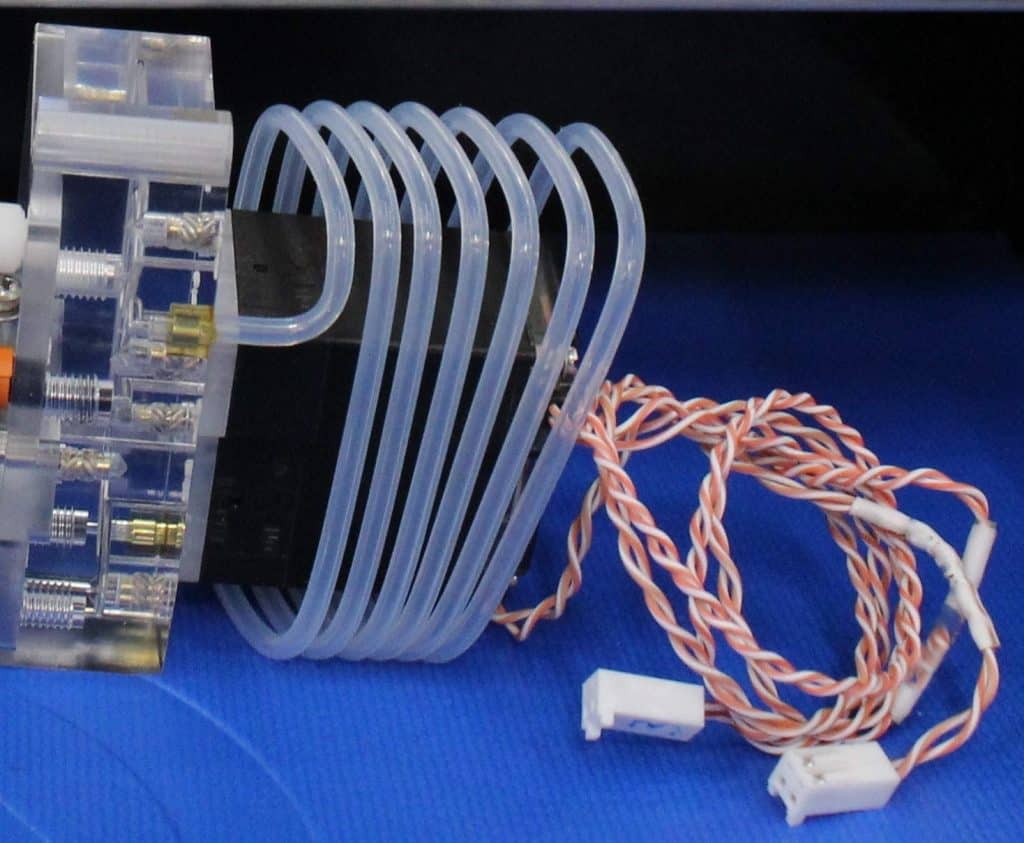

Tubing Assembly Kits for Fluidic Manifold Assemblies

Plastic tubing assemblies control the flow of fluids from entry and exit ports of a manifold assembly, whether carrying samples, reagents, rinse, or waste. These tubing assemblies often pair with our diffusion bonded manifolds to give design engineers confidence and total control over fluid movement in a leak-free, chemically inert environment.

Piedmont CMG offers a wide range of value-added tubing services: Heat shrink labeling, thermoformed bends and coils, flanges, flares, tipping, cut-to-length, kitting, laser etching, ink-jet printing, UV adhesive curing, sterilization, and much more.

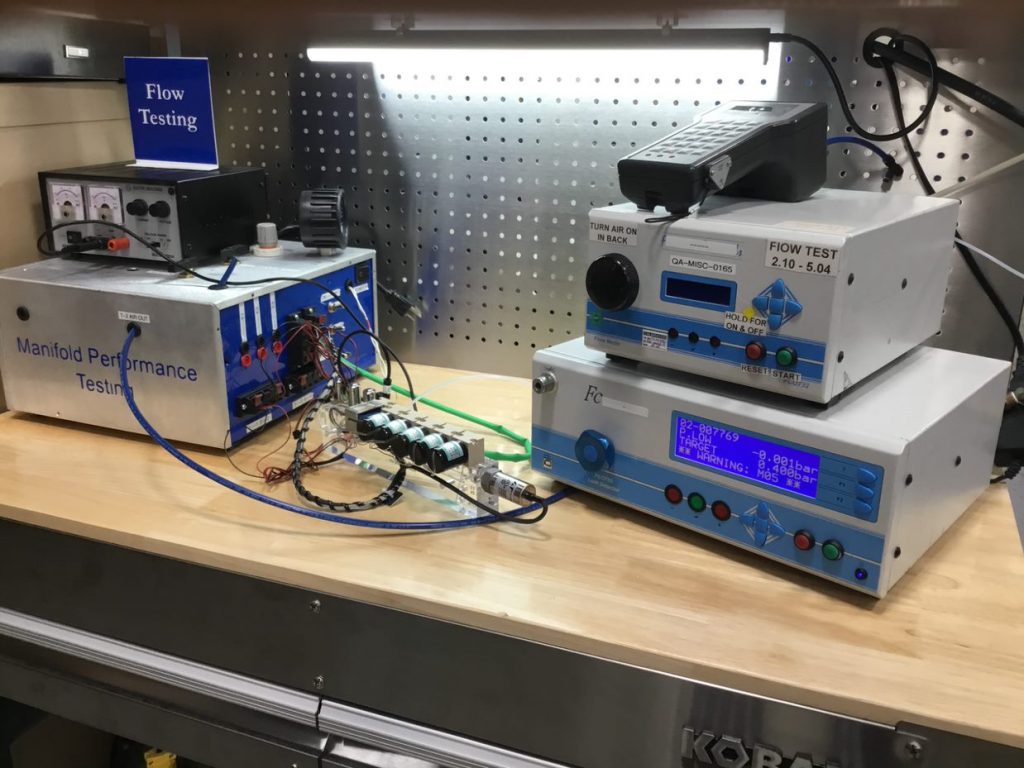

Testing and Validation of Manifold Assemblies

We offer validation and testing services for our fluidic manifold assemblies, pneumatic manifolds, tube assemblies and other fluidic management components. We specialize in offering a turn-key assembly to limit inspection and testing requirements performed by our customers. Whether your device needs functional flow testing, volumetric flow rate testing, leak-decay testing, or electronic testing of the performance of valves, pumps, and circuit connections, let us take care of the testing requirements to deliver a plug-and-play product that’s ready to install right out of the box.

Who Uses Fluidic Manifold Assemblies?

Manifold assemblies are typically utilized by OEMs in the Life Science fields when producing laboratory equipment for testing samples, such as biopharmaceuticals, clinical diagnostics, DNA Sequencing (NGS), IVD, and PCR testing. These devices are used to develop new treatments, pharmaceuticals, and by researchers on the cutting edge of scientific research.