Teamwork & Partnerships

It takes us all. We believe in working together to create innovative new technologies with our customers. We are very proud to partner with industry-leading aerospace and life science companies to manufacture sub-assemblies, fliudic manifolds, tubing, custom fluid containers, and various other fluid transfer devices.

At CMG, we appreciate our partnership with the state of South Carolina, our local communities, local universities and technical schools. Training, studying, and growing are a part of our culture – internships, apprenticeships, and classes to cultivate leadership and professional skillsets.

Industry Leading Technology

We are a technology-driven company that believes in continuous improvement. Industry-leading and proprietary technologies are utilized in our manufacturing operations. Monitors at each workstation display Visual Work Instructions (VWIs) and part specifications to guide production and ensure quality standards.

We have experience working with customer web portals and the implementation process. We coordinate with purchasing departments to lower costs and lead times on prototyping and production-sized orders. Our Rapid Response Team members are experts in JIT manufacturing practices for diffusion bonding, precision machining, and tube assembly kits.

Material Knowledge

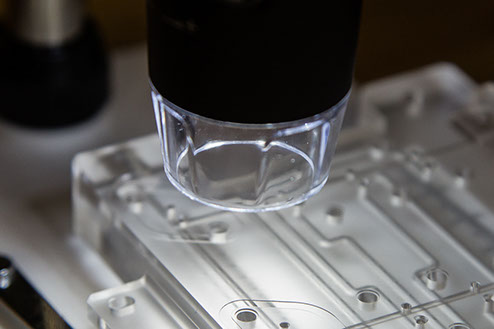

CMG has been machining, bonding, and contract manufacturing plastic components for over 50 years. We assist with R&D, Design, NPI, and lean manufacturing production volume projects. We can help with material selection, DFM, and early product development.

Our capabilities with plastics (polymers) include precision machining, diffusion bonding, annealing, polishing, heat-forming bends / coils, tube flanges and flares, plastic welding, and assembling applications. It’s a unique skillset that allows us to support many applications and industries.

Continuous Improvement

We are constantly improving in all aspects of the business. As a private, family-owned company, we are committed to the ongoing success of our customers, employees, and local communities.

Our culture of continuous improvement has fostered a dynamic team environment that is lean, decisive, and quality-focused. Open communication, new technology, and process controls contribute to innovation and improvement in our capabilities. The result is world-class products that are manufactured in a lean, cost-effective environment.