Why design manifolds with CMG?

With over 50 years of manufacturing manifolds and various fluid handling devices, CMG is well versed in design considerations for all types of fluidic and pneumatic manifolds. We incorporate design for manufacturing aspects from the very beginning, knowing that this will benefit our manufacturing process, the project overall, and the goals of our customers.

What is included in CMG's manifold design service?

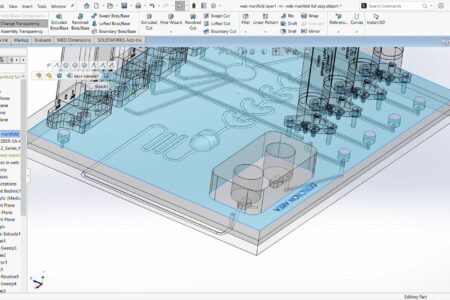

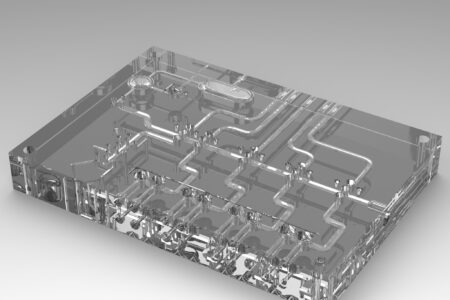

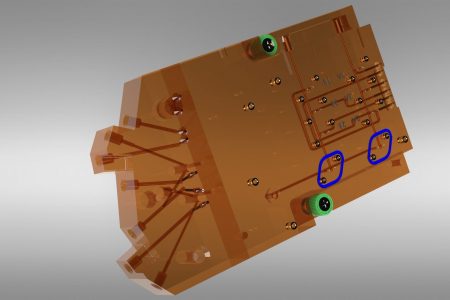

3D CAD Modeling

We will collaborate with your engineering and development team to identify the objectives and performance specifications of your project. Our engineering team will draft potential, competing manifold designs to be tested in flow simulations for factors such as flow rate, pressure, laminar vs turbulent flow, and various other desirable data points.

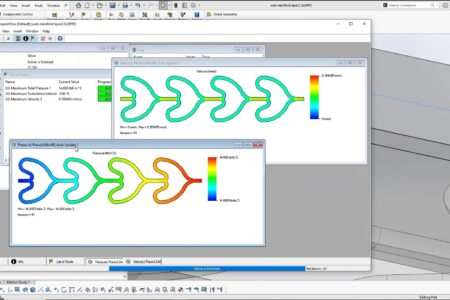

Flow Simulation & Analysis

We utilize the data from flow simulations to optimize flow paths and select the best manifold design for our customers’ applications. We then present the optimized design with a drawing, 3D CAD file, and performance results from flow simulations, along with price and lead time on production of the parts. When our customers are ready, we hand the designs over to our rapid response team to deliver prototype parts in record time.

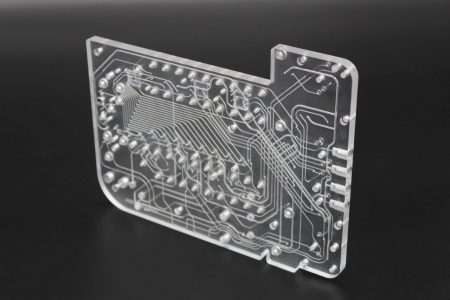

Rapid Prototyping

Once the concept has been reviewed and approved, CMG’s rapid response team will be off to the races to manufacture your prototype parts in record time. This expedited service is capable of turning around new bonded manifold prototypes in as little as 3 weeks.

Additional benefits: Design flexibility & visual clarity

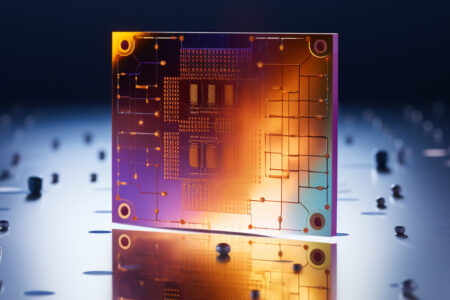

The technology, experience, and capabilities at CMG make it possible for us to design and produce manifolds with unique design configurations utilizing our proprietary diffusion bonding technology. This capability is extremely valuable for OEMs who need design flexibility and fluid flow paths that are free of burrs, defects, or other contaminants. Diffusion bonding technology also incorporates thermoplastic materials that are transparent in nature, creating visual clarity in the final product, which allows for visual inspection of flow paths and entry / exit ports.

What would your team like to create? Contact us to collaborate!