What are High Performance Plastics?

High performance plastics are a group of advanced and strategically manufactured plastics for specific, demanding applications. These materials were developed during the early days of space exploration and subsequently introduced to other demanding applications.

High Performance Plastics Materials of Choice

The following is a list of select high performance plastics materials for precision machining applications:

- Ultem™ (PEI) polyetherimide

- Polysulfone (PSU)

- Polyether ether ketone (PEEK)

- Polyphenylene sulfide (PPS)

- NORYL® modified (PPO) polyphenylene oxide

- Vespel®

- Torlon® (PAI) polyamide-imide

Why Use High Performance Plastics?

These materials typically combine exceptional dimensional stability over a broad range of elevated temperatures, chemical inertness, high strength-to-weight ratio, high flexural strength, high tensile strength, high heat defection temperatures, inherent flame resistance, and many governmental certification compliances. High performance applications in all markets utilize these materials as a low-cost alternative to stainless steel and other metals because of design flexibility, ease of manufacture, and certain material properties that can be selected and specified to obtain specific, desired, repeatable results.

Performance Plastics Material Selection

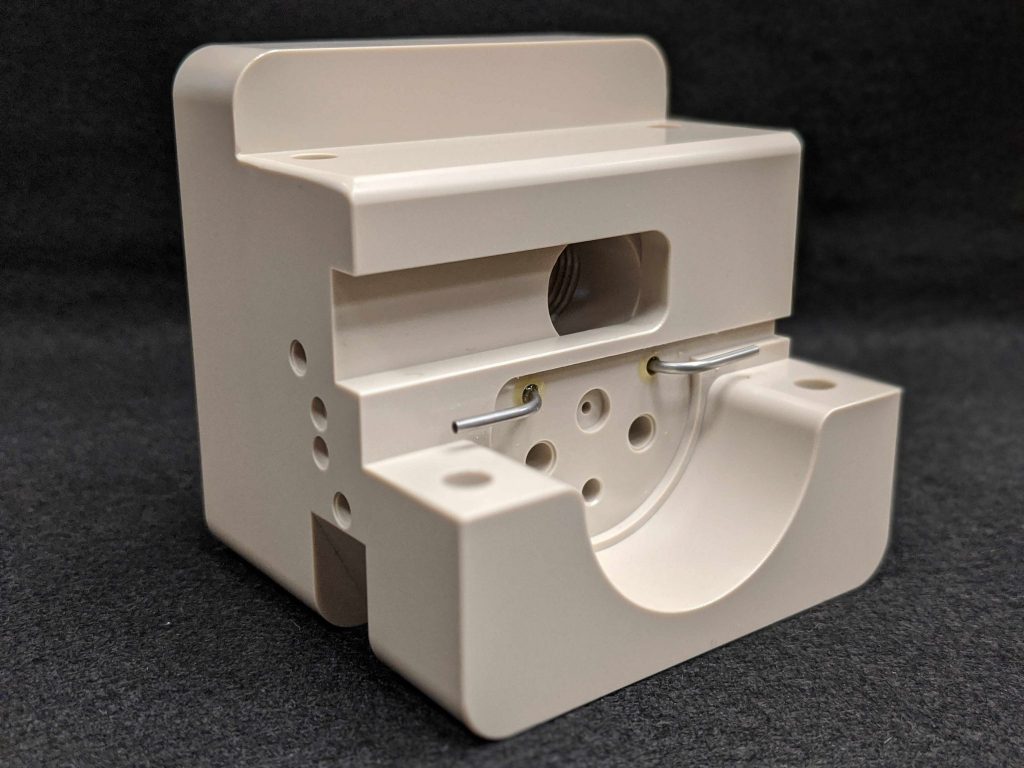

Piedmont CMG can assist in material selection, designing for manufacturability, and early product development. CMG’s niche is in precision machined, formed, and assembled applications – a unique position in the plastics world. Tight tolerances, manufacturing repeatability, and its diversity of manufacturing processes, including diffusion bonding and heat treating, provides CMG with unique opportunities to assist its customers.

Expertise in Machining High Performance Plastics

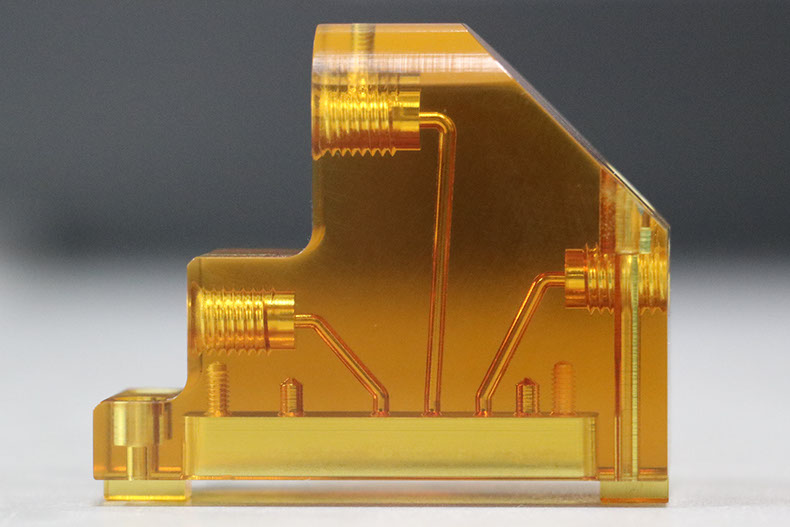

Piedmont CMG specializes in precision plastic materials only. This allows for a clean manufacturing environment without petroleum-based coolants or metal shavings that can contaminate materials. Deep hole drilling, precise intersection of holes, and burr-free parts measured under magnification are standard and normal at CMG. We also specialize in manifolds and other flow applications where dimensional tolerancing, clarity, and burr free intersections are critical to the application.