Secondary Services

Secondary services include a range of operations that are completed during machining cycles as an added cost efficiency to the lean manufacturing production process. The information below elaborates on some of the secondary services offered at CMG. Contact us anytime to learn more.

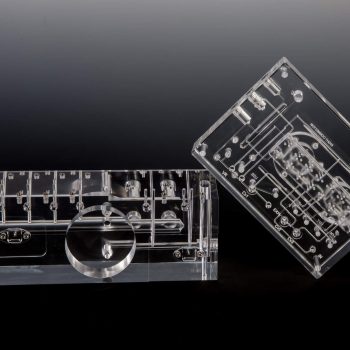

Surface Finish Polishing

Vapor & flame polishing are techniques to enhance the surface finish of amorphous thermoplastics. When done properly, they can greatly enhance the optical clarity of polymer parts.

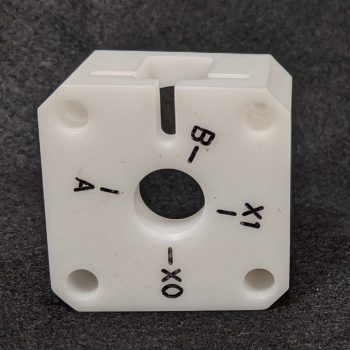

Laser Engraving

Laser Engraving utilizes carbon laser technology to mark or label the surface of a given component. Part numbering, serialization, traceability, and installtion / service instructions are common uses of laser engraving.

Ultrasonic Cleaning

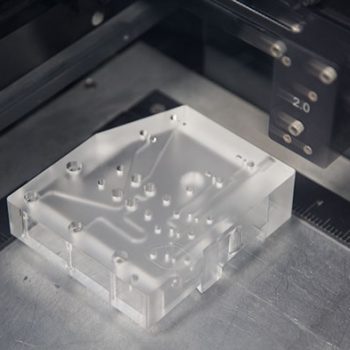

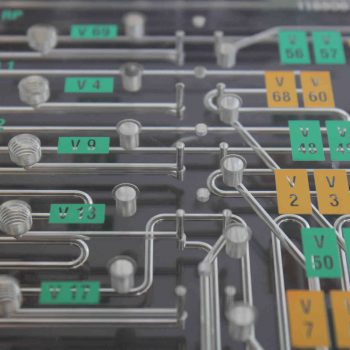

Fluidic Manifold Assembly embodies the full suite of services offered by Piedmont CMG. Our experts assemble and test tubing, sensors, and other components to the desired plastic manifold to offer a complete plug-and-play solution for OEMs in industries such as In Vitro Diagnostics, Aerospace, Oil & Gas, and others.

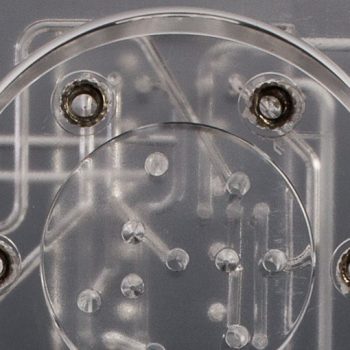

Ultrasonic Inserting

Ultrasonic Inserting is the process of bonding metal inserts into plastic machined parts and manifolds. This is a non-intrusive process that uses no adhesives, so it is perfect for plastic components that require zero-contamination flow with easy connections. Piedmont CMG’s proprietary technique and decades of experience creates the perfect bond between insert and plastic component.

Part Numbering &

Rev Serializing

Part numbering and rev serializing add an important element of traceability to manufactured components. This information can be clearly and permanently engraved or marked onto an open surface of each part.

Paint & Ink Fill

Paint and ink fill make part markings stand out more dramatically. This benefits OEMs during installation, servicing, inspection, and with lot traceability.