What is a Fluidic Management System?

Fluidic systems and solutions provide the means to transfer fluids entering, flowing throughout, and exiting an application. The types of fluids involved vary extensively by industry and purpose, but often include air, blood, chemicals, reagents, sterilizing cleaners, waste, or water. The design, material selection, and integrated components of a fluidic system are highly dependent upon the type of fluid that they are carrying, as well as the devices that they are connected to. Piedmont CMG has the expertise to help engineers identify the optimal materials, components, and design needed to create a fluidics solution for OEMs developing new applications. Let’s take a look at some of the fluidic system solutions that CMG is capable of providing to product design engineers who are developing the fluidic management systems within their device.

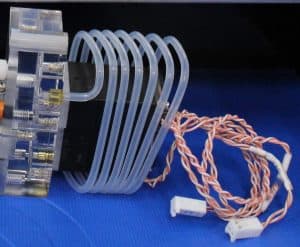

How are Thermoformed Bends and Coils Used in a Fluidic Management System?

An essential consideration for any tubing assembly is the use of thermoformed bends and coils. Bends and coils can help tubing assemblies fit in the tight spaces frequently found in analytical or laboratory equipment. Bends can prevent kinks and navigate the tubing around obstacles or other functional parts of the application. Coils also prevent kinks and take up the slack of move-able arms to prevent entanglement. In addition, coils are commonly incorporated for mixing and other fluidic-processing laboratory requirements. Similar to our flanging capabilities, the heat-formed bends and coils manufactured by CMG are precise, consistent, and repeatable.

Labels and Markers for polymer Tubing Assemblies

Labels or markers are a quick, easy, low-cost method of including useful information directly on the tubing assembly. Markers can be strategically located on an assembly to provide useful information to the user, such as: part numbers, connection instructions, or even the type of fluid that will be flowing through the tube. This information can be printed directly on the tube via laser-etch or ink-jet printing, or with labels added to the exterior of the tube such as UV glued or heat shrink labels. Regardless of your preferred method of labeling, Piedmont CMG is capable of quickly and reliably manufacturing them to your specifications.

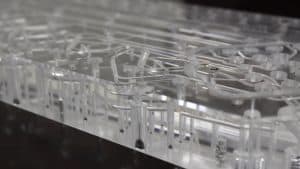

Tubing Kits for OEMs

For OEMs looking to simplify the tubing requirements of their fluidic management system, tubing kits are an excellent option. Tubing kits allow a customer to assign a single part number to an entire kit of tubing assemblies that are required for any given device or application. Instead of sourcing many different parts and materials, CMG can manage this step for you to greatly simplify procurement, installation, service, and replacement efforts. Each tubing kit will contain all of the pieces, pre-assembled, that are needed to make secure connections for an entire device or specified function of the device. Tubing kits are assembled and shipped in pre-arranged bags so that all you have to do is open the bag and install. It’s a truly “plug and play” fluidic solution.

Tubing assemblies are an indispensable part of fluidic management systems, but CMG has much more to offer OEMs who are looking for a total fluidics solution. Be sure to check back soon to learn more about designing a fluidic management system with our other capabilities, including: fluidic manifolds (machined and diffusion bonded), bottle and cap assemblies (for water, waste, and reagents), as well as flow testing and other fluidic validation services.