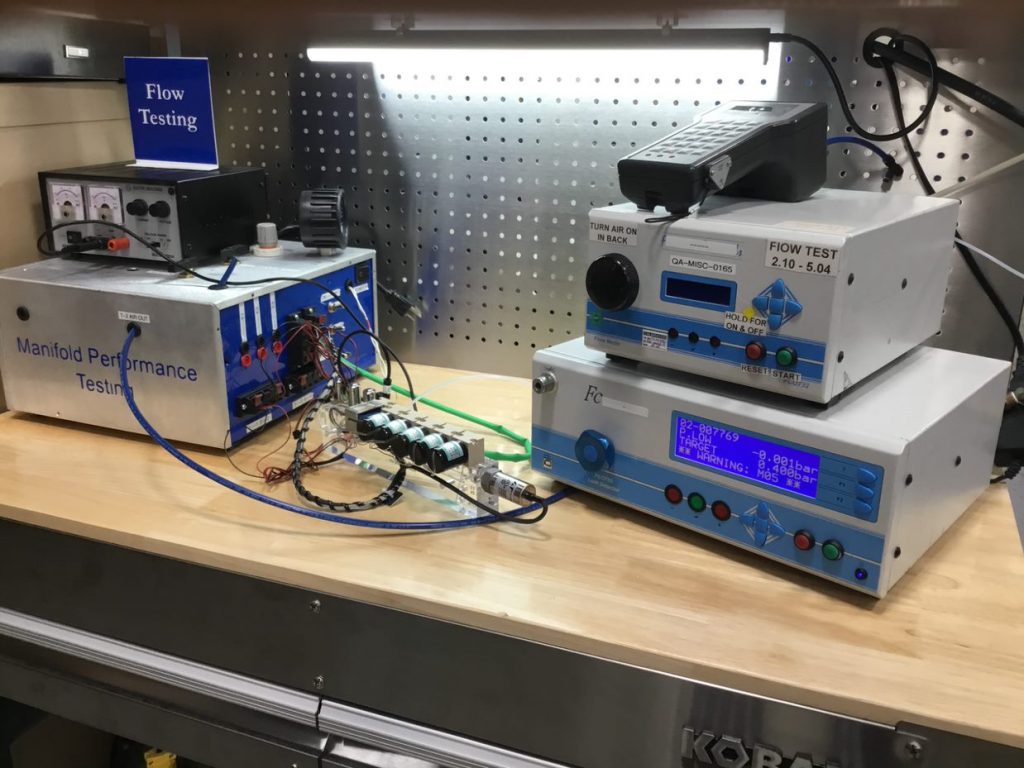

What is a Functional Flow Test?

A fuctional flow test is a performance check on manifolds and manifold assemblies to ensure that fluidic flow paths are operating properly and within defined parameters. This test applies pressure to the part using digital instrumentation to determine if there are any obstructions within the channels that might affect performance and flow rates.

CMG performs Functional Flow Tests to ensure there is no complete or partial blockage in fluidic passageways. The tests can be performed with water or air. The parameters for the tests are specified by customers or by using industry standards.

Benefits of Functional Flow Testing for

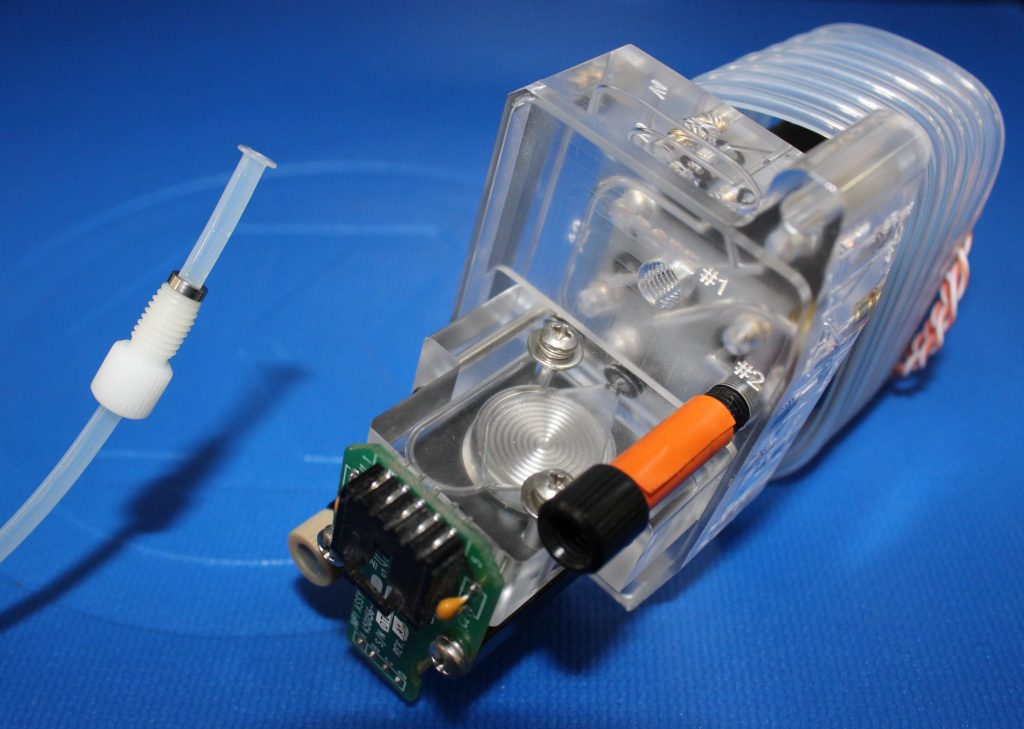

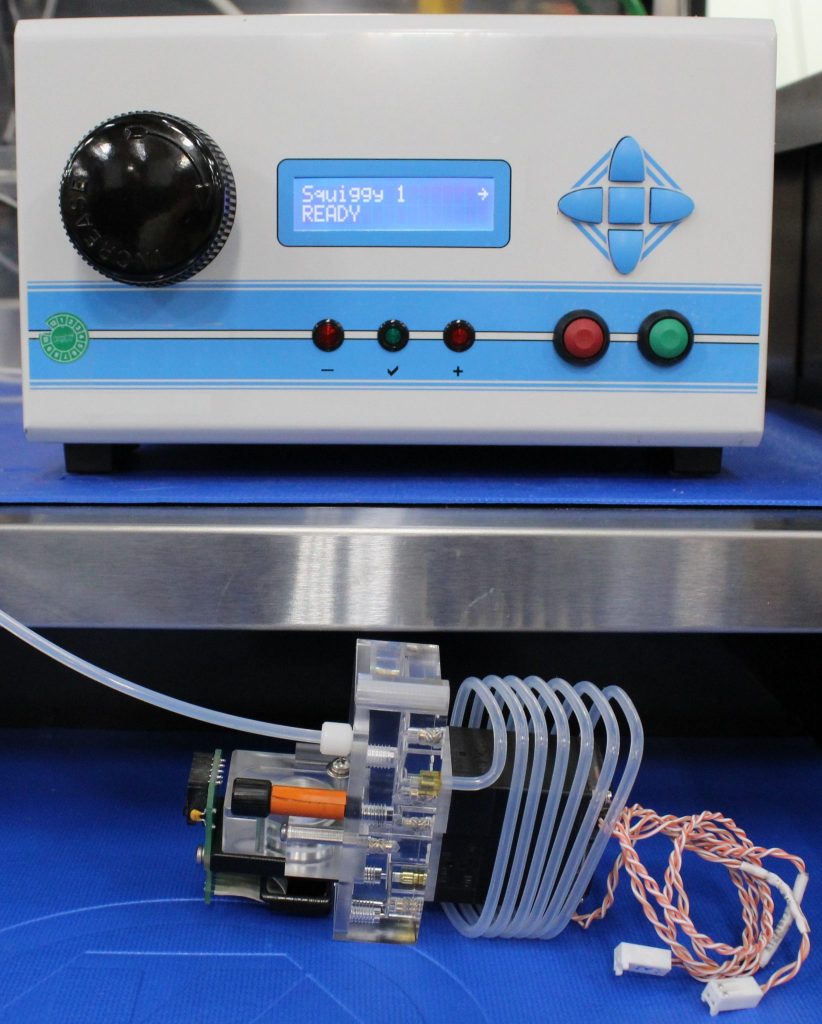

Manifold Valve & Tubing Assmblies

Complete or partial obstructions in fluid paths are detrimental to the proper functionality of manifold assemblies. A typical obstruction could be a burr created during machining that has not been properly expunged. Many burrs are invisible to the naked eye. CMG’s pressure test will identify the blockage so it can be removed.

Functional Flow Testing Service for OEMs

Many customers do not have the capabilities to test as thoroughly as CMG’s Functional Flow Test. In these instances, if the manifold has not been tested properly, there is a risk that the customer will install the manifold assembly into their instrument with blockages that could lead to instrument failures in the field. CMG’s testing eliminates that risk.

For customers that do have testing capabilities, CMG’s Functional Flow Testing allows our partners the ability to outsource the time-consuming testing and validation of critical device components.