(CAB) CELLULOSE ACETATE BUTYRATE Key Facts

Cellulose Acetate Butyrate (CAB-UVEX®) is manufactured by the chemical modification of cellulose, a naturally occurring polymer derived from wood pulp. The cellulose is modified by adding acetate and butyrate to form a transparent thermoplastic.

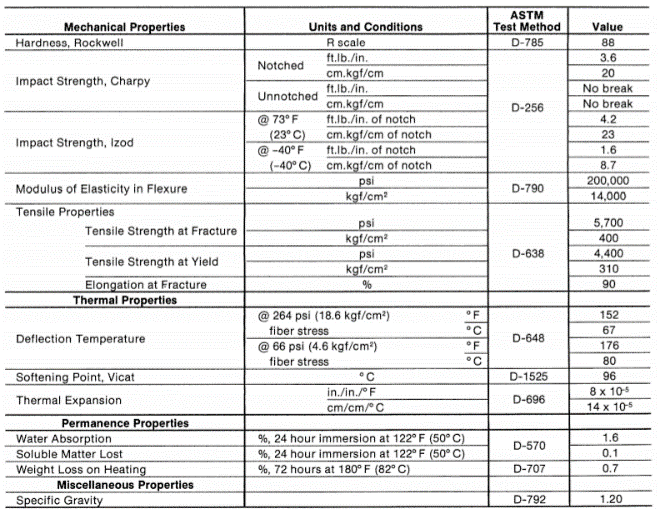

Cellulose Acetate Butyrate possesses excellent impact strength, even at low temperatures. This property is also combined with other outstanding characteristics such as transparency, colorability and durability.

Key Features of (CAB) CELLULOSE ACETATE BUTYRATE

Transparency

An excellent thermoplastic for multi-duty applications where clarity and impact strength are required.

Weather Resistance

This UV inhibiting cellulosic is frequently used in the production of outdoor sign faces where high impact is required.

Formability

The ease with which CAB may be thermoformed allows for high cycling production on semi-automatic and automatic vacuum formers.

Impact Strength

The excellent impact strength of this material has allowed it to replace expensive metal machine guards.

Sound Barrier

This material offers excel lent dampening characteristics to meet O.S.H.A. noise requirements.

Applications of (CAB) CELLULOSE ACETATE BUTYRATE

- Machine Guards

- Bottle Line Covers

- Skylights

- Gasoline Pump Faces

- Retail Displays

- Gauge Covers

- Housings