PEEK Key Facts

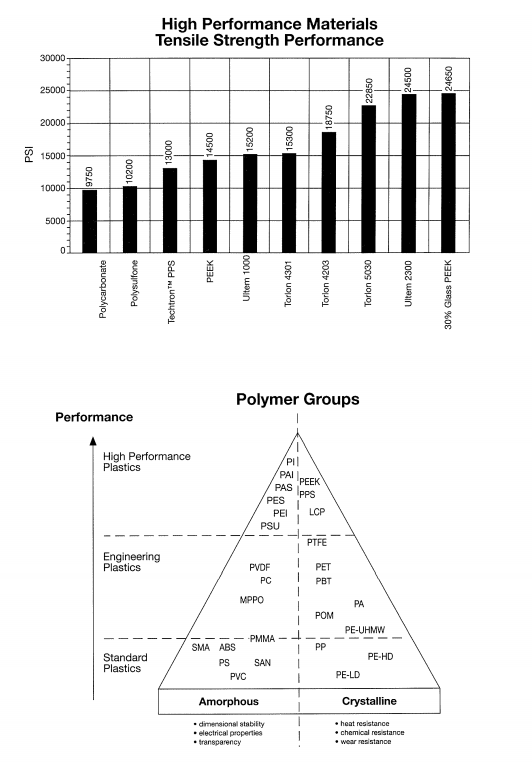

PEEK is a semi-crystalline, high temperature resistant, engineering thermoplastic with exceptional chemical resistance, fatigue endurance and thermal stability. PEEK also exhibits excellent mechanical and electrical properties.

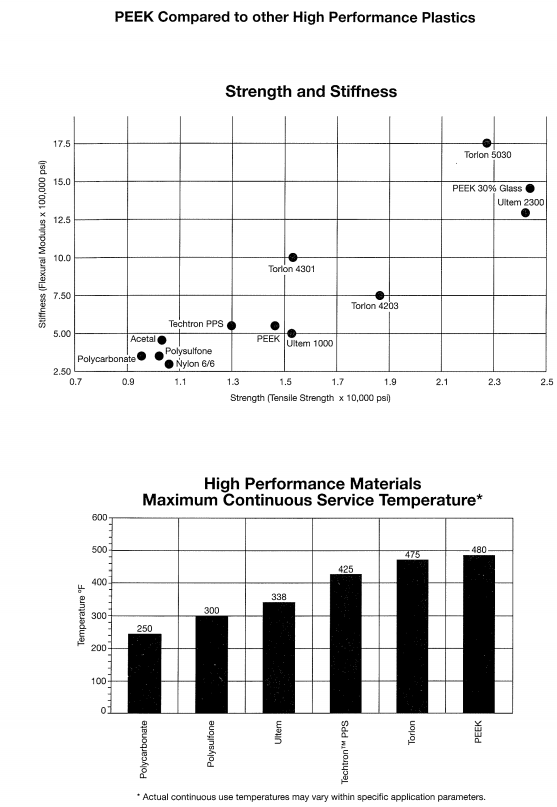

PEEK has a maximum continuous working temperature of 480°F (250°C) and has excellent retention of mechanical properties up to 570°F (300°C). In a steam or high pressure water environment, PEEK can be used for thousands of hours at temperatures of 480°F with no significant degradation of properties.

Superior chemical resistance has allowed PEEK to work effectively as a metal replacement in extremely harsh environments. It is inert to all common solvents and has excellent resistance to a wide range of organic and inorganic liquids. PEEK is also exceptionally resistant to high levels of alpha beta and gamma radiation and is rated UL-94-V-O (.060″ tk) with extremely low levels of smoke and toxic gas during combustion.

Key Features of POLYETHER ETHER KETONE

- PEEK continuous service temperature estimated at 480 degrees F. (UL746B)

- Second highest chemical resistance out of High Performance materials

- Highest heat deflection temperature among HP materials when 30% glass is added (600°F)

- Long term service temperature of 480° F

- Excellent slide and wear properties

- Biocompatible

- Flammability V-0

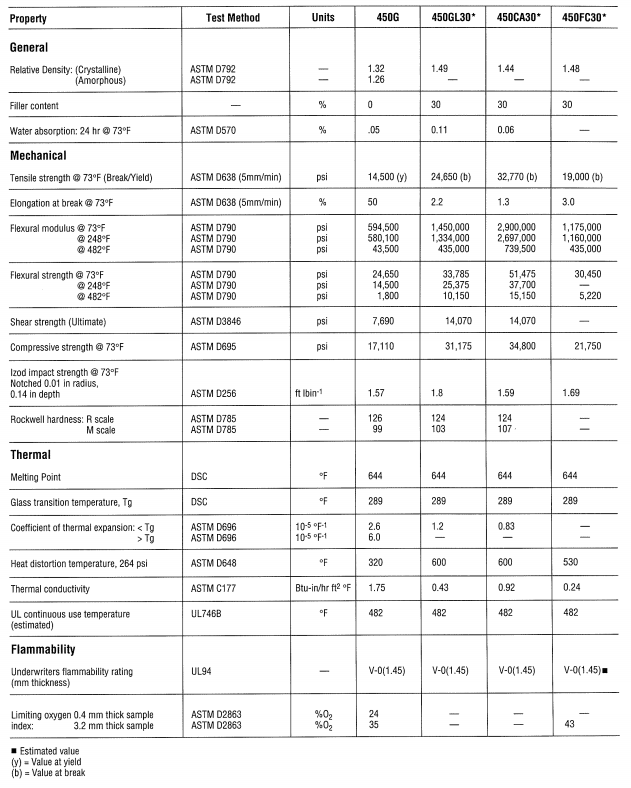

Key Properties of PEEK

Chemical Resistance

PEEK exhibits excellent resistance to a wide range of organic and inorganic chemicals. The compatibility of PEEK with many chemicals at 20°C (68°F) has been investigated and the results for unreinforced grades are given in the table. These results are derived from tests in which unstressed specimens were completely immersed in a wide range of chemical environments at room temperature. They may differ considerably from those found in service. Especially in the effects of stresses and strains set up during fabrication, and of elevated temperatures. These conditions, particularly those of stress and strain, are difficult to reproduce in the laboratory. The table, therefore, should be used only as a guide, and the user should satisfy himself beforehand of the suitability of PEEK for the in-service environment. PEEK also performs outstandingly well in aggressive environments at high temperatures.

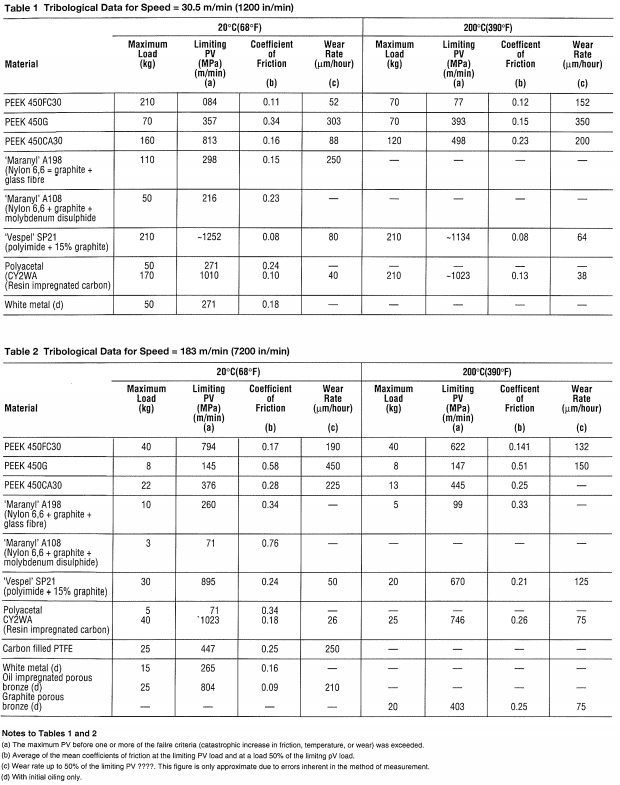

Wear Resistance

PEEK and blends of PEEK with other materials offer excellent tribological properties under a wide range of conditions.

High Temperature Performance

PEEK has an estimated continuous service temperature (UL746B method) of 250°C (480°F) with excellent mechanical properties retained to temperatures over 300°C (570°F).

Hydrolysis Resistance

PEEK can be used for thousands of hours at temperatures in excess of 250°C (480°F) in steam or high pressure water environments without any significant degradation in properties.

Radiation Resistance

The resistance of PEEK to gamma radiation at high dose levels is exceptional for a plastics material.

Flammability

PEEK has a V-0 flammability rating down to 1.45mm (0.057 in) without the use of additives. (Underwriters’ Laboratories test result).

Smoke and Toxic Gas Emission

The levels of smoke and toxic acid gas released during combustion are extremely low for a thermoplastic material.

Electrical

The excellent electrical properties of PEEK remain stable over a wide range of temperatures and frequencies.

Typical Applications of POLYETHER ETHER KETONE

- Aerospace/Automotive components

- Military defense applications

- Steam cleaning equipment

- Insulators and connectors

- Integrated circuit carriers

- Pump and valve seats/seals

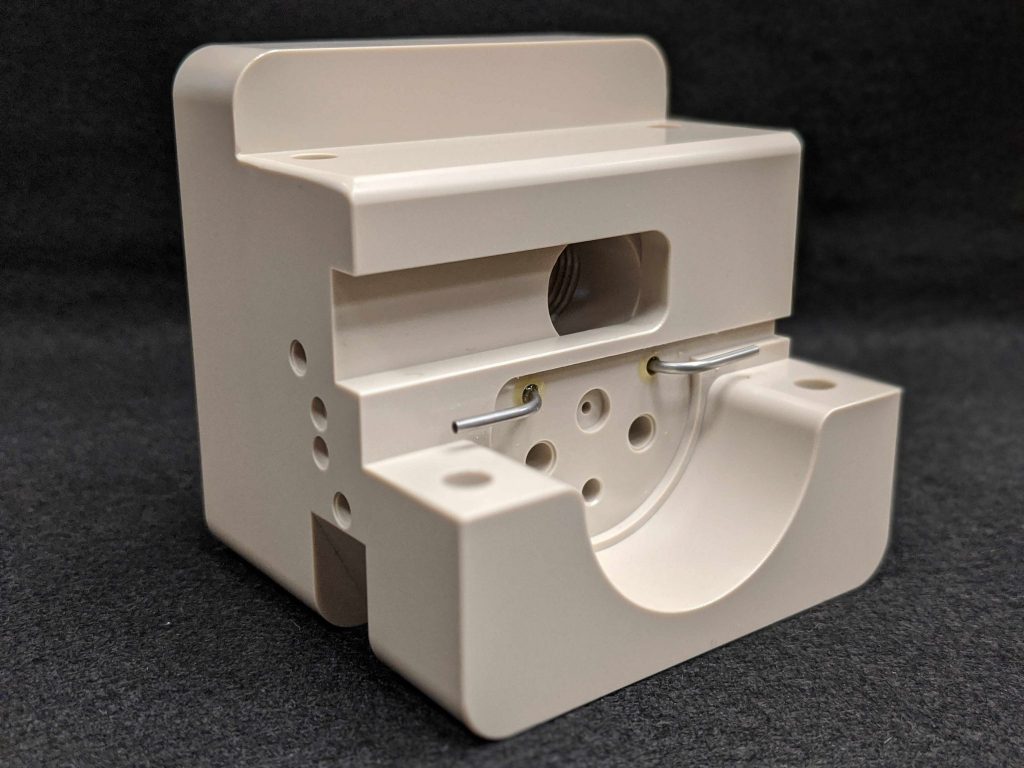

- Housings, rotors and impellers

- Flowmeters

- Bushings, bearings and rollers

- Oil drilling tool components

- Machined Manifolds

- Fluidic Components