POLYCARBONATE Key Facts

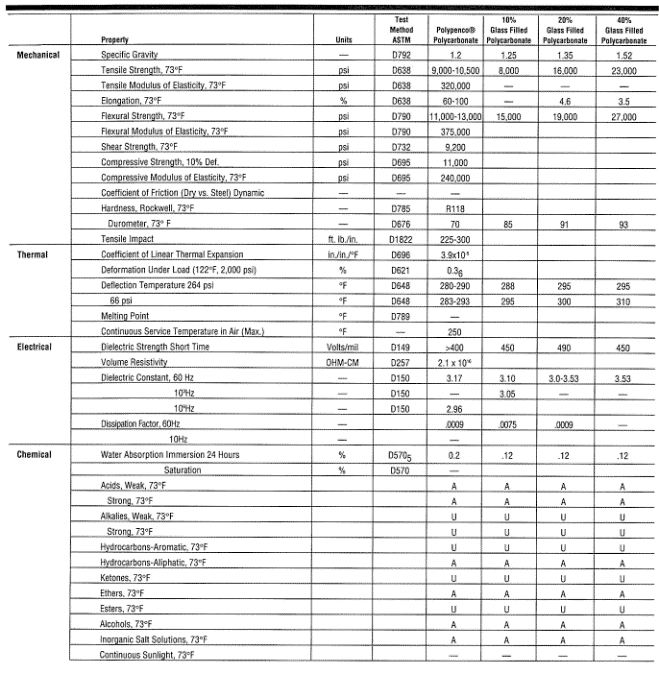

Polycarbonate is a transparent thermoplastic which offers very high impact strength and high modulus of elasticity as a machined part. The material has a high distortion temperature and absorbs almost no moisture. These properties, in addition to good electrical characteristics, make polycarbonate a prime material for electrical/electronic applications. Its strength, impact resistance and transparency also make it an ideal material for certain transparent structural applications.

Polycarbonate mill shapes are produced from polycarbonate resins which meets the requirements of Federal Specification LP-393a.

Polycarbonate is readily machined on standard metalworking equipment. It can be drilled, sawed, turned, shaped, milled, punched, filed, sanded and buffed.

Key Benefits of POLYCARBONATE

- High impact strength

- Excellent strength retention at elevated temperatures

- High tensile, shear and flexural strength

- High modulus of elasticity, low deformation under load

- Excellent resistance to creep and cold flow

- Low coefficient of thermal expansion

- Good electrical insulation properties

Applications of POLYCARBONATE

- Coil forms

- Insulators

- Connectors

- Rollers

- Impellers

- Fittings

- Handles

- Instrument windows

- Covers