POLYSULFONE UDEL® Key Facts

Polysulfone is a high performance thermoplastic known for its high temperature resistance, hydrolytic stability and excellent machinability. These characteristics have helped polysulfone replace metals, glass and ceramics in a wide variety of applications.

Polysulfone possesses good resistance to a wide variety of aggressive environmental conditions. Polysulfone is also highly resistant to aqueous mineral acids, alkali, and salt solutions. The material’s resistance to detergents and hydrocarbon oils is also good, even at elevated temperatures under moderate levels of stress. Polysulfone also exhibits exceptional steam resistance, including exposure to high temperature and pressure conditions. Its resistance to radiation is the highest known among plastics

Polysulfone’s long-term resistance to environmental stress cracking has opened up many new application areas where the user can take advantage of the bonuses of economical fabrication and light weight products. These areas include chemical processing equipment, food processing components and piping, gas scrubbing and pollution control devices, filtration equipment, and parts involving contact with highly caustic environments.

Key Features of UDEL®

- Resistant to Radiation

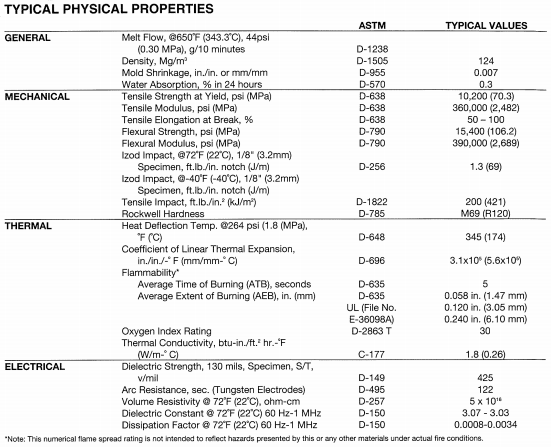

- Very High Tensile Strength

- Good chemical resistance

- Autoclavable

Applications of POLYSULFONE UDEL®

- Electronics

- Medical Devices

- Pacemakers

- Respirators

- Lab Equipment

- Machined Manifolds

- Automotive

- Aerospace Machined Parts

- Food & Beverage Equipment