Contract Manufacturing Performance Plastic Products

We Manufacture Plastic Products To Your Specifications

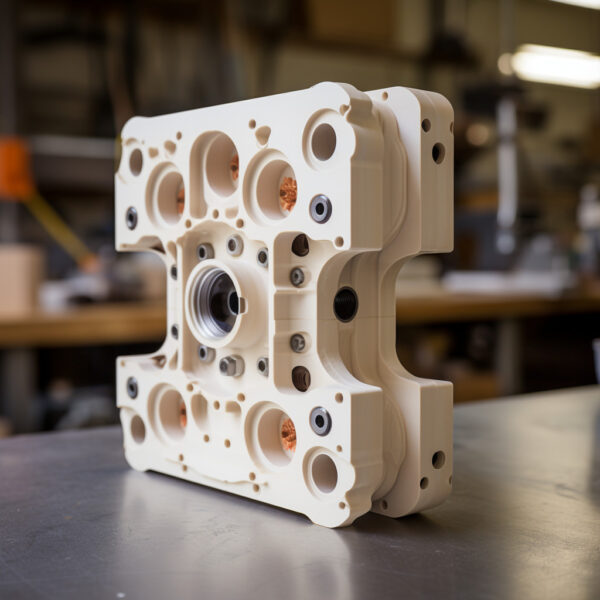

Piedmont CMG is a contract manufacturer of plastic products. We employ talented technicians who utilize the latest in CNC equipment, tools, and technology to produce critical parts and components for our customers around the world. We manufacture, inspect, and certify products to your specifications with full traceability in a lean manufacturing environment.

Exclusive Focus & Experience In Performance Plastics

Our core competency is manufacturing cost-effective, custom plastic products. We do not work with metals or other materials. This plastics focus benefits our customers through our knowledge of materials, proprietary machining techniques & technology, and design for manufacturing (DFM) reviews that come standard on project quotes. Cut costs and lead times with Piedmont CMG – focused exclusively on plastics for decades.

Plastic Materials We Work With

We have experience with just about every type of plastic material in production. From commodity plastics, to high-end performance plastics used in Aerospace, we have the knowledge and skill to deliver custom parts with tight tolerances that meet your specifications.

Acetal (Delrin)

Delrin AF

PEEK

PPS Tecatron

Torlon (PAI)

Acrylic (PMMA)

Polysulfone Udel (PSU)

PET

PVC Polyvinyl Chloride

Ultem (PEI)

Celazole (PBI)

PBT Hydex / Tecadur

PPO Noryl

Radel (PPSU)

Vespel Polyimide

Products Certified To Your Specs

We are happy to provide a Certificate of Conformance on products provided, ensuring the inspection and quality of our work meets or exceeds your requirements.

Exceptional Customer Service

You can always reach our customer service team with a phone call during normal business hours – try it now! You will find a helpful, on-site employee who is ready to support you.

Critical to Function Parts & Components

We are proud to be on the critical supplier list for many of our customers due to the critical-to-function nature of many products we manufacture.

100% Made In USA

100% of our manufacturing work is completed in our two facilities, both located within the United States.

Services & Capabilities

Piedmont CMG offers a range of contract manufacturing services to support the production of custom plastic products that meet our customers’ requirements.

Volume & Expedited Production Capabilities

We possess the capacity and capability to offer both large volume production and quick-turn, expedited orders for our valued customers.

Design For Manufacturing (DFM) Part Review

We incorporate a DFM review on all new parts to ensure each job is lean and efficient – minimizing prices and lead times on every project.

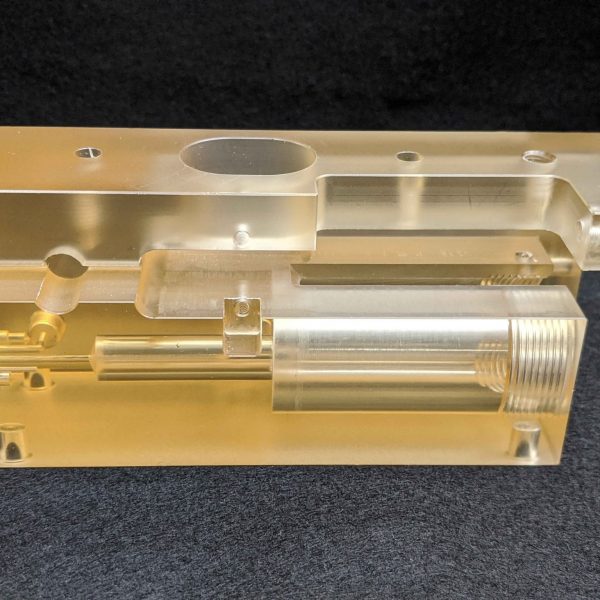

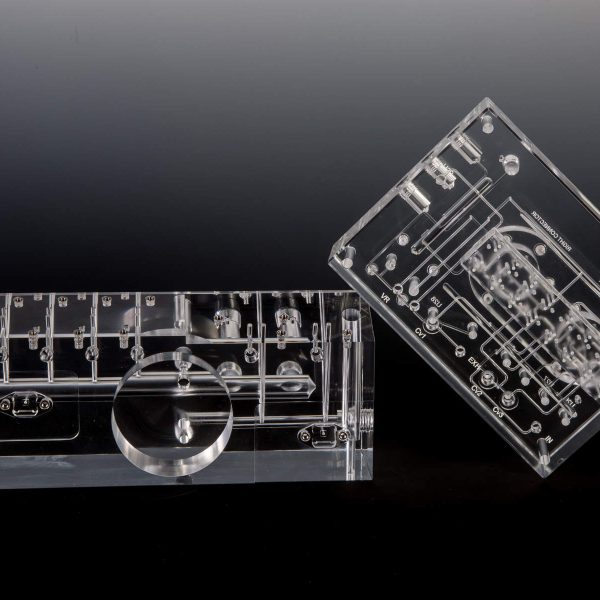

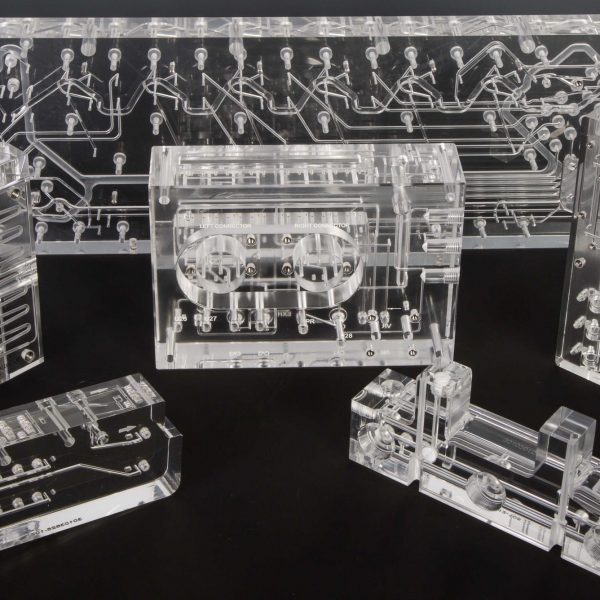

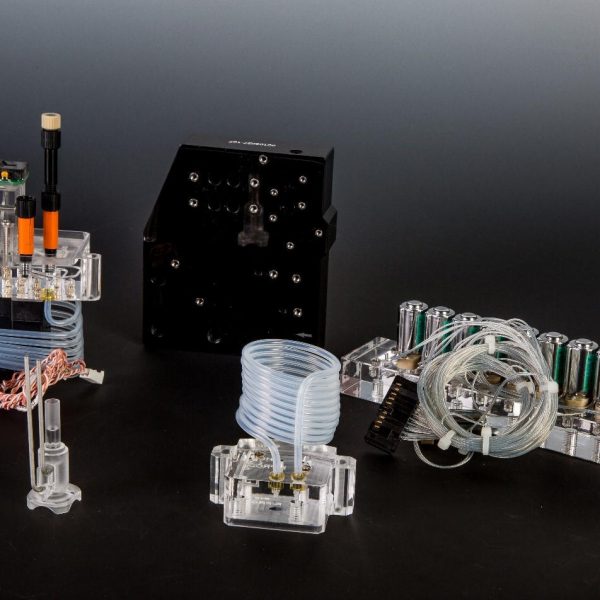

Assembly & Value-Add Operations

Many of our projects require assembly of components such as valves, pumps, sensors, degassers, tubing, or other functional device. We also routinely add metal inserts to attach components and laser engraving to mark part numbers and functions.

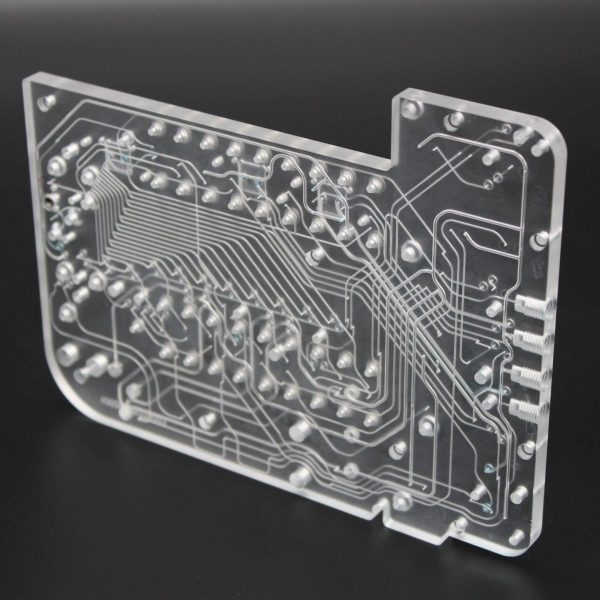

Surface Finishing & Polishing

Our advanced plastics machining capabilities achieve high quality surface finishes right off the machine. However, we do offer polishing and buffing for parts that require a glossy, glass-like surface finish.

Expert Quality & Short Lead Times at Competitive Prices

Find out for yourself. Get a free quote & DFM review on your project!

Plastics Machining Expertise

With an exclusive focus on plastics, Piedmont CMG has decades of knowledge and insight into the best practices, techniques, and procedures to produce repeatable, quality products.

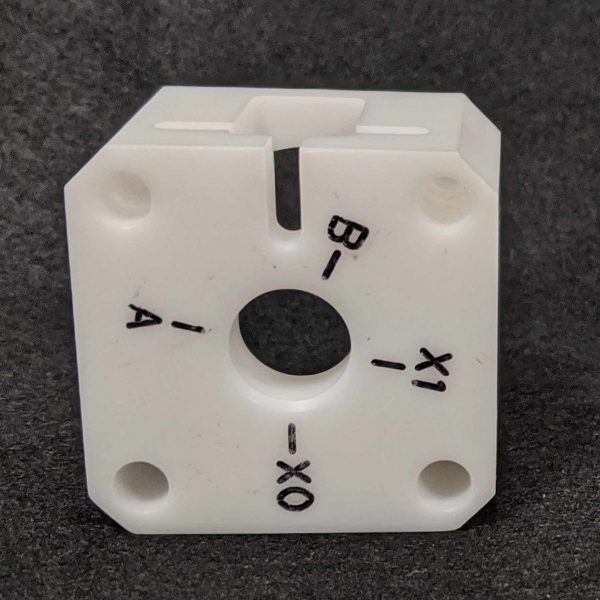

Tight Tolerances & Quality Results

Tight tolerances are a common requirement for many of our customers’ applications. We have developed the expertise, control systems, and technology to routinely achieve the top quality results that keep us on the preferred supplier lists.

Proprietary Techniques & Technology

Plastic materials have a wide range of physical, thermal, and chemical properties. Many of them need specific processes of annealing, machining, and tooling for quality results that reduce residual stresses and perform as designed.

Lean Manufacturing & Continuous Improvements

We have cultivated a culture of lean manufacturing and continuous improvement, with constant investement in equipment, training, and eliminating waste from our processes. Our stated manufacturing quality goals are 0% customer returns and 100% on time delivery.

Visual Work Instructions

Electronic visual work instructions (VWI) are utilized at every workstation in our two facilities. The VWIs provide guidance and instruction to operators, and contain invaluable data on manufacturing processes for each job.

In-Process Inspections

Technicians inspect – and are responsible for – the quality of their own work. Electronic imaging inspection systems ensure accuracy and traceability, while providing the speed and ease-of-use that allows operators to inspect products without leaving their workstation.

In-Process Value-Add Operations

Our process flows are streamlined to complete value-add operations during CNC machining cycles. Ultrasonic metal inserts for attaching hardware and laser engraving for marking parts are common additions to our plastic products.

Live Data Scheduling System

Piedmont CMG developed a proprietary software system to share live production data between our two facilities via fiber optics. This powerful asset aids scheduling and management in keeping jobs on time and minimizing changeovers.

Strategic Supplier for Industry-Leading Companies

We are very proud to partner with Fortune 100 companies and industry leaders across many markets around the world. Doing our part to support new medical treatments and discoveries, new defense technologies, and delivering quality, safe products to consumers is both motivating and inspiring to the Piedmont CMG family.

Rave Reivews From Supplier & ISO Quality Audits

We welcome new supplier audits. Piedmont CMG consistently exceeds requirements and expectations with our QMS and procedures. Ask us about a virtual audit and/or virtual tour.

Long-Standing Repeat Customer Relationships

There is a reason we have customer relationships that have lasted for decades. A combination of quality products, on-time deliveries, and unbeatable customer service give no reason to look anywhere else.

Traceability From Raw Material To Finished Product

Piedmont CMG procures materials directly from the manufacturers. This provides us with traceability and cost-savings that we pass on to our customers. Our processes and QMS ensure we meet the stringent traceability requirements of medical and aerospace applications.

Experienced Vendor For a Variety of Markets & Industries

Our plastics manufacturing experience spans across life science, aerospace, medical, food & beverage, defense, oil & gas, semiconductor, and other industries around the world. We embrace new challenges and look forward to meeting the demands of new markets in the days ahead.

Ready to start your new project? Get a free quote & DFM review.

Want To Learn More About Piedmont CMG?

Check out our Video Introduction

A short YouTube video introduction that dives into our culture, capabilities, and the type of work we do for our customers around the world.