What is stress cracking in plastics?

Stress cracking is an internal or external crack in a plastic caused by tensile stresses, which can be either an applied stress or a residual stress already present in the material. Inexperienced plastics machinists may experience this issue in a range of plastic materials, including acrylic (PMMA), polycarbonate (PC), and even Ultem (PEI).

What causes stress cracking in acrylic and other amorphous polymers?

The processes utilized in manufacturing plastic materials – especially extrusion – create internal stresses. As the diameter or thickness of the material increases, the internal stresses grow accordingly. Materials must be annealed to relieve these internal stresses. However, it must be done properly and thoroughly – incorrect annealing only increases the amount of stress present. All subsequent manufacturing steps also add stress to the material: machining, drilling, tapping, inserting, gluing, etc. Therefore, additional annealing is required. Proper annealing is a lengthy process involving hours and days, not minutes or seconds, and again varies by material type and thickness.

Crazing vs Cracking

Crazing in plastic materials is generally defined as a surface-level defect. Crazing is a warning sign of stress that is present in the material, and that a small amount of additional stress could lead to catastrophic failure.

Cracking is essentially the material’s way to relieve stress. A crack demonstrates that enough stress was present and/or applied to the material to force the molecules to break apart along the polymer chain. A crack can mean complete failure for a plastic part, especially in fluidic applications.

How to prevent stress cracking in Ultem and other plastics

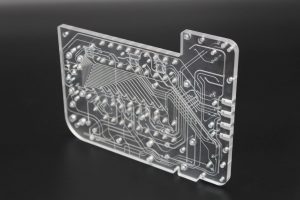

To prevent stress cracking from occurring in amorphous polymers such as acrylic, polycarbonate, and Ultem, one needs a depth of knowledge regarding plastic material properties, stress-relieving heat treatment (annealing), and proper machining techniques for the material being processed. Stress can be introduced at any point in the manufacturing process, from production of the raw material all the way through finishing and polishing.

The good news is, Piedmont CMG has extensive experience and knowledge in the proper techniques for every type of plastic on the market. Whether you need a PEEK pump head with threaded ports, a bonded manifold for mounting valves, or other custom, contract manufactured plastic application, contact us and work with the experts for a turnkey solution that takes the stress out of your supply chain.