Technology and Industry: Two Sides, One Coin

When looking at industrial applications, innovation and efficiency are key drivers for success. While some industries continue to seek the latest cutting-edge solutions to optimize standard processes and overcome operational challenges, others are already finding answers with fluidics. Fluidics is a field rooted in the manipulation of fluid dynamics, and offers an exciting, efficient alternative to many challenging industry questions in fields like aerospace and life sciences. Join the experts at Piedmont CMG as we share a bit about fluidics, its history, and the value it brings to our OEM partners.

What is Fluidics?

Fluidics is the science of using fluid interactions to operate a control system. That may sound like a lot to unpack, but at their foundation, fluidic devices function on the same premise as electronic circuits. An integrated circuit, for example, is an arrangement of components (transformers, resistors, etc.) that functions to guide electrical input toward a specific output. On the other hand, fluidic devices utilize fluid flow and pressure to reach that desired output. These devices take advantage of the strength inherent in a fluid’s adaptable nature, and the possibilities are myriad. Speaking of circuits, it is even possible to design fluidic circuits that perform the same logic functions used in electronic devices. Is it possible to build a computer with fluidics? It is, and people have!

A Storied Past

Nikola Tesla patented the first fluidic diode in 1920, but Billy M. Horton of Harry Diamond Laboratories is credited with launching the field of fluidics in 1959, when he came up with the idea that amplification can be reached by using one fluid stream to deflect another. He and his colleagues published their results following the creation of several working vortex amplifiers, and the world took notice. Seeing that fluidics could be used to manage sophisticated control systems, several industries turned to it for answers to their various needs. From intrigue and ingenuity, Billy Horton grabbed the world’s attention, and a new technological field was born.

Power in Flexibility

Bruce Lee once famously stated, “Be shapeless like water.”. He would go on to describe water’s ability to form into whatever shape it is put into. “You put water into a cup, it becomes the cup. You put water into a bottle, it becomes the bottle.”. For Bruce Lee, this idea of adapting to circumstances was the philosophical control system for his martial arts. In fluidics, this adaptability is shared by many more fluids than water alone and is the fundamental physicality that makes fluidic control systems potent and diverse.

What Can Fluidics Do For You?

With the right fluidic applications, mechanical parts like valves, actuators, sensors, and mixers can be rendered obsolete. These moving parts and others have analagous counterparts in fluidic systems; and their functions can be achieved without relying on the fallible nature of mechanical parts and electronics. The solid-state nature of fluidic systems brings with it a host of benefits. Let’s dig deeper into why that matters, and what it means for various industries.

No Moving Parts

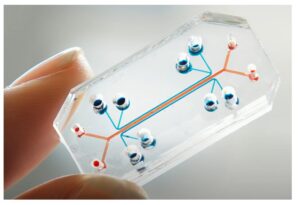

A solid-state device or assembly can reduce the need for maintenance and the risk of mechanical failure, making fluidic systems more reliable and durable than their mechanical counterparts. This reliability means companies enjoy lower maintenance costs over a device’s lifetime, as well as an increase in safety – particularly in industries where equipment failure could threaten lives. Not all devices are completely solid-state, but some, like lab-on-a-chip (LOC) technology are. Nevertheless, every fluidic component that replaces traditional mechanical parts contributes to operation safety and variable cost savings.

Compact

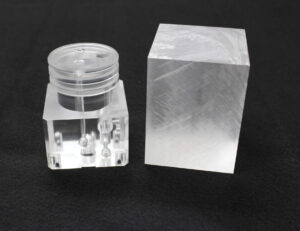

Fluidic systems are designed to be compact and to use space efficiently. Because they often need not rely on bulky mechanical components, they can be integrated into tight spaces. This quality in many fluidic devices, coupled with lightweight thermoplastic components, has and continues to revolutionize industry around the world.

Contamination-Free

Requiring no lubricants or seals means that fluidic manifolds are less likely to become contaminated. Coupled with thermoplastic diffusion bonding, these manifolds are perfect clean environments for hosting crucial medical research processes like flow cytometry.

Versatility

Fluidics offers versatility in terms of fluid selection. Different types of fluids can be used in fluidic systems depending on application requirements. Furthermore, modern machining techniques make it possible to create complex mechanisms from an array of materials. This inherent flexibility allows for a wide range of applications in various fields, such as chemical processing, biomedical diagnostics, and environmental monitoring.

Something For Everyone

Be it research toward more efficient and quiet flight with fluidic thrust vectoring, or cutting-edge advances in cytometry that blend acoustic and fluid manipulation, it’s clear that the field of fluidics is more influencial than ever in the world around us. Industries around the globe saw the potential in Billy M. Horton’s proof-of-concept and over six decades since of dedicated research and development have brought the world to where it is today in the field of fluidics. We at Piedmont CMG are proud to be a part of that legacy and proud of our OEM partners that tirelessly strive to bring their best and brightest ideas to life.